When it comes to venting appliances, the roof is the most commonly used exit point. However, there are a number of reasons why this might not be the best choice—or even possible—and you have to start considering other options, such as a wall or soffit (the underside of the roof overhang, or eaves).

The International Residential Code (IRC) doesn’t talk about soffits in reference to dryer ventilation. But, it does provide enough information for us to come to certain conclusions about this practice. In addition to the question of can you or can’t you, you must consider if you should and how.

Dryers can be vented through the soffit if it is not prohibited by the manufacturer. All other dryer installation regulations provided in the IRC must also be met. Notably, the dryer vent must not be within 3 ft of an opening into the building, including passive soffit vents. Never vent into the soffit.

The IRC Does Not Prohibit Venting Through Soffits

Whenever I am making an alteration to my house, whether it’s something simple, like installing a new bathroom door, or something more complex, like venting an appliance, I always start by checking the building codes.

Sometimes the code will explicitly say you can or cannot do something. However, if the codes were to plainly say everything that you can and cannot do, they would be ridiculously long and extremely difficult to navigate. As such, some rules are implied through a collection of adjacent regulations.

In the case of venting a dryer through a soffit, there is no explicit statement of yes or no. However, we can suppose it to be acceptable as long as venting through the soffit does not contravene any of the venting rules found in Section M1502 of the IRC, which governs Clothes Dryer Exhaust.

Soffit Dryer Vent Positioning

According to IRC M1502.3:

“Exhaust ducts shall terminate on the outside of the building. Exhaust duct terminations shall be in accordance with the dryer manufacturer’s installation instructions. If the manufacturer’s instructions do not specify a termination location, the exhaust duct shall terminate not less than 3 feet in any direction from openings into buildings, including openings in ventilated soffits.”

This means all exhausted dryer air must be released outside, which makes sense when you think about all the damage moisture-laden air can do inside a house!

Venting through the soffit would meet this requirement of exhausting outside.

You can get an idea of just how bad it is by reading my article on Reasons Why Having No Ventilation in a Bathroom is Terrible.

The IRC often gives final installation authority to manufacturers, such as is the case here. The reason for this is that all dryers are different and to govern their installation in the same way could end up creating problems.

If your dryer manual says “do not vent through a soffit”, or “vent the dryer through the roof” then to go through the soffit would be contravening building codes.

Where manufacturers don’t specify the terminal vent location, we fall back on the IRC’s “backup” rules, i.e., the vent must be at least 3 ft from openings in the house. Distance from openings is something that would be included in manufacturer instructions, so either way, it is considered to be important.

This makes universal sense because it prevents exhausted air from flowing out of the duct and straight back into the house.

The IRC specifically mentions openings in ventilated soffits in this context because passive soffit vents are frequently used to ventilate attics and other upper-story rooms.

If you can’t vent the dryer through the soffit so that the exit is more than 3 ft away from all of the ventilated panels, then venting through your soffit would contravene the code.

Printable Dryer Venting Checklist

Never Vent Into a Soffit

Before we look at if you should or should not vent through a soffit if you can without contravening the manufacturer instructions or the rules in the IRC, let’s clear up something really important—the difference between “through” and “into”.

While the IRC does not prevent you from venting your dryer through the soffit, it does state clearly in Section M1501.1 that a dryer may not be vented into a soffit.

“The air removed by every mechanical exhaust system shall be discharged to the outdoors in accordance with Section 1504.3. Air shall not be exhausted into an attic, soffit, ridge vent, or crawl space.”

There are two main reasons for this prohibition:

- It would cause a buildup of moisture in the soffit, walls, and attic, which can lead to structural damage, electrical damage, rust, and mold. Furthermore, it can attract rodents and insects into your attic and lead to animal-related damage and bacterial growth.

- The second reason is that lint will build up in the soffit, walls, or attic, which poses a severe fire hazard for the home.

Benefits of Venting a Dryer Through a Soffit

Although less common than roof venting, there are several benefits of venting a dryer through a soffit.

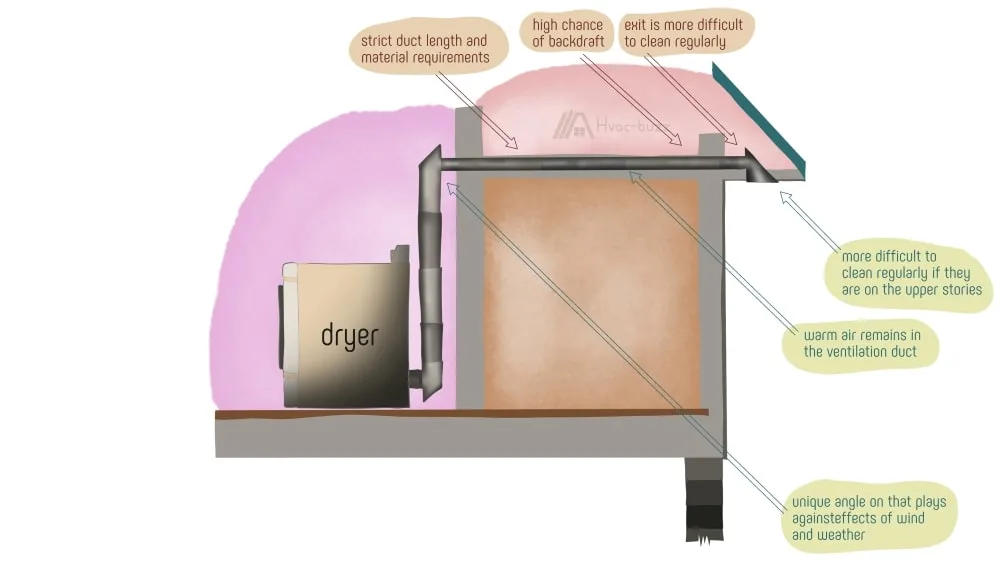

Minimized Effects of Wind and Weather

Installing the terminal vent of a dryer exhaust in the soffit means that the vent has a unique angle on the underside of the rooftop. Wind seldom flows strongly at this angle, thus very little wind-related backdraft is possible.

The vent will also be less likely to cause leaks in your house because of its sheltered position in the eaves (when was the last time you saw rain being directed upwards!).

No Need for Hole Through Your Roof

By installing a dryer vent through a soffit, you do not need to create a new hole through your roof. If your roof is already housing your attic vents, bathroom exhaust vents, plumbing vents, etc., then the dryer vent may overcrowd your rooftop.

Furthermore, using a soffit vent helps to keeps your house leak-free because every time you make a new hole in your roof, there is a certain degree of compromise to the weatherproofing and you naturally increase the risk of leaks.

May Be the Shortest Route

If your dryer is not located in an upper-floor bedroom, then running the dryer ducting to the soffit is a shorter route compared to running it to the roof. Since the shorter the route, the better, this should factor into your decision.

Drawbacks of Venting a Dryer Through a Soffit

There are also several drawbacks of venting a dryer through a soffit. These disadvantages are:

Short and Straight Requirements

To operate efficiently, dryer ventilation systems should be as short and as straight as possible. This will, unfortunately, dictate where the ventilation exit can be located.

For dryers in basements or other below-ground locations, the best location for the vent would be at or near ground level, which is not near the soffit, so it is not a viable option.

If the dryer is located in a central room, you will have to assess the route to the soffit; if it involves too many turns, then it might exceed the allowable ducting length for dryers, which we discuss later on in this article.

Backdrafting

Another drawback of venting a dryer through a soffit is that the exhausted air is warm and naturally wants to rise.

So, a backdraft damper is required to prevent the hot air released from the vent from entering the ducts again.

Backdraft dampers are a requirement anyway, so this is not an unnecessary addition. However, it does make backdraft damper failure more problematic.

Soffits on Upper Stories Lack Accessibility

Another drawback of venting a dryer through a soffit is that the soffit dryer exit is more difficult to clean regularly if they are on the soffits of upper stories as the vent will only be accessible with a ladder.

However, it is vital that the vent be cleaned regularly in order to prevent lint buildup and outside debris (including animals and nests) from collecting onto the exit. Such a buildup creates a significant fire risk.

Furthermore, the debris buildup can cause decreased efficiency and reduced speed of airflow.

Since these soffit vents are out of sight, they are more likely to be forgotten by the homeowner and not maintained.

It is important to note that soffit vents are considered to be more accessible than roof vents as long as they are not on the soffits of upper stories.

All Normal Installation Regulations Still Apply

Manufacturer Instructions Take Precedence

As I mentioned previously, IRC Section M1502.3 says that dryers should be installed and vented according to the manufacturer’s instructions.

Each clothes dryer is designed to be vented a certain distance, withstand particular conditions, and operate in a specific manner. Thus, it is important to understand that the dryer manufacturer’s instruction manual takes precedence in terms of installation.

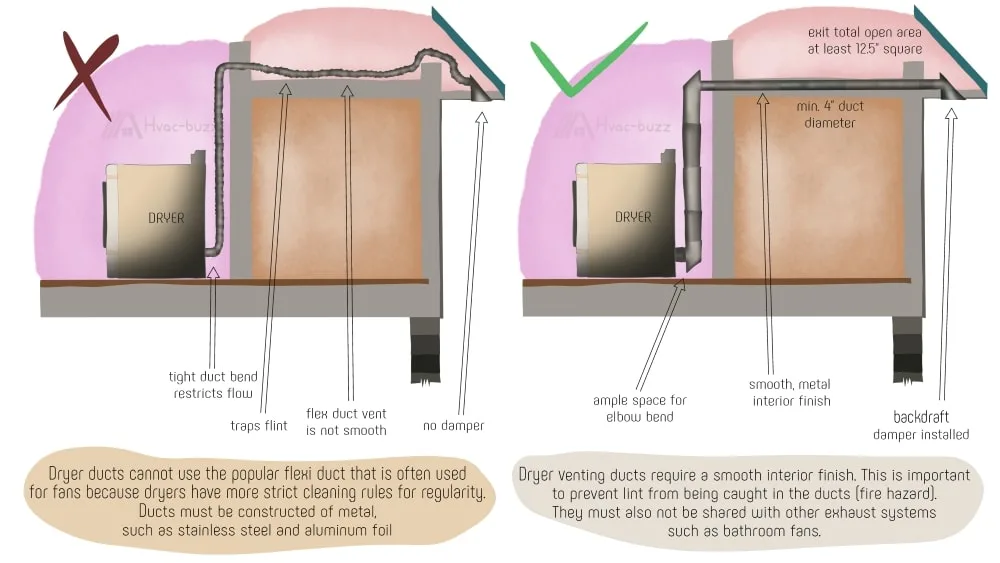

Dryer Vent Opening Dimensions

According to the IRC Section M1502.3.1, the total open area of the dryer exit must be at least 12.5 square inches (8065 mm2). This is to ensure that the vent actually allows adequate air exhaustion and ensure proper ventilation.

Correct Ducting Material and Size

Dryer vents require specific ducting material and a complimentary duct size so that there is a tight fit and no leakage.

Both the material and size required to make ducting a successful addendum to soffit dryer ventilation vary based on the dryer and soffit system.

However, the IRC does stipulate three non-negotiable rules in Section M1504.1:

- Venting ducts require a smooth interior finish. This is important to prevent lint from being caught in the ducts (fire hazard). These means that foil ducting is not permitted.

- These ducts must be constructed of metal, such as stainless steel, with a thickness no less than 0.0157 inches or 0.3950 mm. This means that plastics like PVC and ABS are not permitted.

- The duct must be four inches (102 mm) in diameter.

Dryer vents can never be shared with other exhaust systems. This is stipulated in Section M1502.2 of the IRC:

“Dryer exhaust systems shall be independent of all systems and shall convey the moisture to the outdoors. Exception: this section shall not apply to listed and labeled condensing (ductless) dryers.”

This rule stems partially from the differences between the two ventilation systems. A dryer vent and another ventilation system often have different protocols. For example, dryer ducts cannot use the popular flexi duct that is often used for fans because dryers have stricter cleaning rules for regularity.

Thus, if a dryer vent and another ventilation system were combined, there would be material incompatibility because the same type of ducts cannot be used for both ventilation systems and this becomes inefficient to operate.

But more importantly, this rule exists because there are significant dangers associated with combining a dryer vent with another exhaust system, such as a bathroom fan. For more information, read through my article on Can Bathroom Fan and Dryer Share a Vent.

However, the rule extends to two dryers sharing a vent. Even though they have the same material and dimension requirements, shared vents mean multiplied risk.

Duct Installation Requirements for Soffit Dryer Vents

The IRC doesn’t just cover the materials and dimensions for dryer ducting, it also looks at the actual mechanics of installing the ducts. This information is found in Section M1502.4.2.

It’s a lot of information in a single paragraph, so instead of quoting it, I will break it down for you with the reasons why (which I always find helpful).

You have to support the ducts at intervals and these supports must be added every 12 feet (at least). Supporting the ducts helps to prevent sagging.

The choice of minimum 12 feet intervals is not arbitrary. While they do not state this in the IRC, you can assume that they did some testing and found intervals over 12 feet resulted in significant sagging with common ducting materials.

Sagging is quite a nightmare for exhaust systems. It causes pooling of moisture, collection of lint, and just generally interferes with the efficiency of airflow through the duct.

The supports also reduce stress on the ductwork, minimizing the risk of breakages over time.

Ducts have an insert end and an end into which the insert end of another length of duct fits. The IRC specifies that the inserting end must face the direction of airflow.

While the lip of the insert is very slight, it has the ability to impact airflow (creating turbulence, which slows the air down) and it can trap lint (flammable), which is why this stipulation was included.

Sliding the ducts together is not sufficient. The IRC requires the ducts to be secured together and in place.

Fasteners must be mechanical (i.e., screws or something similar and appropriate). They must not protrude into the interior of the ducts more than 1/8 inches. As with the insert lips, protruding screws or other fasteners can interfere with airflow and collect lint.

Sealing can be done with welds, gaskets, mastics, liquid sealants, or tapes, but these must be designed to handle the pressure and heat involved in dryer exhaust systems.

Where the ducts run through enclosed spaces, they cannot be compressed or deformed in any way. The importance of an undeformed duct is to protect its integrity over time and to ensure that the airflow is unimpeded as it carries exhausted air through the soffit.

Allowable Length of Ducting Between Dryer and Soffit

According to the IRC Sections M1502.4.6.1–M1502.4.6.3, the longest allowed exhaust duct length is determined by the design of the exhaust duct system.

Section M1502.4.6.1 states the following:

“The maximum length of the exhaust duct shall be 35 feet (10 668 mm) from the connection to the transition duct from the dryer to the outlet terminal.“

However, for each additional dryer duct exhaust fitting, you decrease this length by a specific amount. You can veiw Table M1502.4.6.1 of the IRC for these reductions, but as an example, adding a 4″ radius mitered 45-degree elbow means that you must subtract 2 ft and 6″ from the 35 ft maximum.

The reason for this is that each additional fitting decreases the airflow efficiency of the ductwork and humid air from the dryer will only be exhausted properly over a shorter distance.

Manufacturer directions will, of course, take precedence when it comes to maximum ducting length, but the information above can be used when there are no instructions. Furthermore, you will likely find that the manufacturers adhere to the maximum length of 35 ft with reductions for fittings.

No Screens

According to Section M1502.3, screens are not permitted to be installed at the duct termination region. This is because lint will build up on the screen and create a blockage.

Lint build-up is not only a hindrance to effective ventilation, but it is also a potential fire hazard.

Install a Backdraft Damper

As I mentioned earlier, you have to install a backdraft damper with dryer exhaust ducts.

A backdraft damper is a device that operates with a movable plate or two blades. These are designed to allow air to flow through the exhaust duct to the outside but prevents the outside air (and the exhausted air) from flowing back into the ducts.

This is particularly important for dryers that vent through the soffit because the air is exhausted down as opposed to up (like through a roof vent).

It is essential to understand the direction of airflow before you purchase your damper. Gravity dampers only operate with an upward or horizontal airflow and will not operate with a downward airflow, which is what we get with soffit vent terminations.

I recommend AC infinity backdraft dampers. Try to avoid the cheap plastic ones. They are usually not rubber-sealed nor spring-loaded. This means that they will leak cold air into the house and could be noisy when windy.

- An antidraft duct insert designed for use with range hoods, bathroom fans and other home HVAC applications.

- Features outer rubber gaskets that create an airtight seal and grip between the damper and ducts.

- Mounts horizontally or vertically to prevent backflow and debris from entering ducting.

- Galvanized steel body with spring-loaded aluminum damper blades that open with minimal airflow.

Last update on 2024-03-28 / Affiliate links / Images from Amazon Product Advertising API

How Do You Install a Soffit Dryer Vent?

You can ask an installation/repair person to install a soffit dryer vent into your house for a fee, or you can install it yourself after purchasing the parts required (check for any permits you may need).

This activity may take several hours, so it is recommended to set aside an afternoon, or even a full day if you are a novice, for installation.

| Tools you may need | Amazon link |

| Corded drill | View |

| Drill bit set compatible with a corded drill | View |

| Tape measure | View |

| Metal snips | View |

| Screwdriver (slotted, Phillips, Square/Roberton, and Torx Aka/Star) | View |

| Caulk gun | View |

| Materials you may need | Amazon link |

| Soffit vent cap (remember to get one without a screen!) | View |

| Damper | Included with vent cap |

| Duct cap | – |

| Foil tape (aluminum tape is okay but duct tape will not work) | View |

| Exterior caulk | View |

| Pipe straps | View |

| 4″ ducts | – |

| 4″ elbows | View |

- Identify the shortest and straightest route for the ductwork to the soffit.

- Purchase the materials you may need (remember to ensure they are IRC-compliant). Purchasing materials specifically designed for dryers will be your safest bet.

- Ensure the cap sits correctly on the siding by drilling a test hole into the rim joist.

- Adjust the test hole to fit the siding of the vent cap.

- Drill the vent hole into the siding with a hole saw.

- Drill through the rim joist.

- Insert the vent and screw the cap into the home by pushing the foam backer rod into gaps and caulk.

- Cut the vent to length with metal snips and wear the correct hand wear (thick gloves).

- Close the seam on the dryer vent.

- Tape the elbow joints with the aluminum foil tape.

- Attach the first vent section and then the remaining sections by sliding the elbows of the vents into the crimped ends.

- Secure the dryer vents to the walls with pipe straps.

- Test the dryer vent by turning on the dryer and observing that the vent flap is opening. If not opening, restart from step 1.

For more in-depth instructions to install a soffit dryer vent, see this website for step-by-step pictorial descriptions.

Below is a helpful video on how to install a soffit vent.

Is the Dundas Jafine Soffit Dryer Vent Really Good

When I was researching the best soffit dryer vents, Dundas Jafine all but monopolized the search results. But what makes them so popular?

The Dundas Jafine soffit dryer vent is a safe, economical purchase for soffit dryer vents. By searching on their website for “dryer vent”, there are over 24 options for customers to choose from!

The vents are made from ultraviolet-resistant plastic which protects the cap from the deleterious effects of the sun, they come with a built-in damper, they can be painted to match the home’s color easily, and they weigh only 2.5 lbs.

- Enables you to exhaust a dryer through the soffit of your home, instead of standard wall venting

- Contains a UV resistant coating to prevent the cap from discolouring and is paintable to match the soffit on your home

- A large damper on the front opens when the dryer is turned on to exhaust the air, then closes when the dryer is off

- This helps to prevent cold air, rain, or snow from entering the home and acts as a guard against pests and rodents from entering the duct

Last update on 2024-03-28 / Affiliate links / Images from Amazon Product Advertising API

Consider a Ventless Dryer

After going through this article, if you realize that you are unable to vent through the soffit (and you were looking at the soffit because the other options were eliminated), why not consider a ventless dryer?

Ventless dryers have an internal system to remove moisture without the need for an external vent. Hot air moves into a condensing chamber where it is cooled, allowing the moisture in the hot air to condensate.

This water is then collected and stored in a container below the machine and is emptied out either through a pump system or manually.

Benefits of ventless dryers:

- They can be installed anywhere as there is no ductwork that needs to reach the outside.

- They are not as invasive as vented dryers and do not require cutting holes into your home.

- You will never have to worry about a cold draft coming through your dryer vent.

Drawbacks of ventless dryers:

- They are more expensive compared to vented dryers

- Some models do have pumps that empty out the water for you, but some models require someone to manually empty the water.

Sources

https://allurausa.com/blog/what-is-soffit

https://dryerbox.com/dryer_venting_guide.htm

https://www.thewizway.com/dryer-information-maintenance/benefits-of-a-clean-dryer-vent/

https://homeguides.sfgate.com/dryer-roof-venting-systems-95568.html

https://www.conservationmart.com/t-Search.aspx?keywords=backdraft+dampers

https://www.familyhandyman.com/project/how-to-install-a-dryer-vent/