When looking to have installation installed, there’s a lot to consider! While comparing materials, prices, pros and cons, and quality, things can get overwhelming fast.

To make things easier on you, I’ve taken all the basics you’ll need to know about cellulose insulation and put them together in one spot. So, without further delay, let’s dive right into the nitty gritty.

Cellulose insulation is treated paper waste products with a 20-30-year lifespan. It is gray with bits of color and has a wooly texture. The R-value is 3.2-3.8 and is mostly loose-fill or dense-packed. It costs $0.80-1.20 per sq. ft. It contains chemicals that can be a health risk to sensitive individuals.

What Is Cellulose Insulation?

Cellulose is a wood fiber-based insulation used within the home. Like other types of insulation, it helps to reduce the loss of heat from the home (or the entry of heat into the home) and mitigate noise.

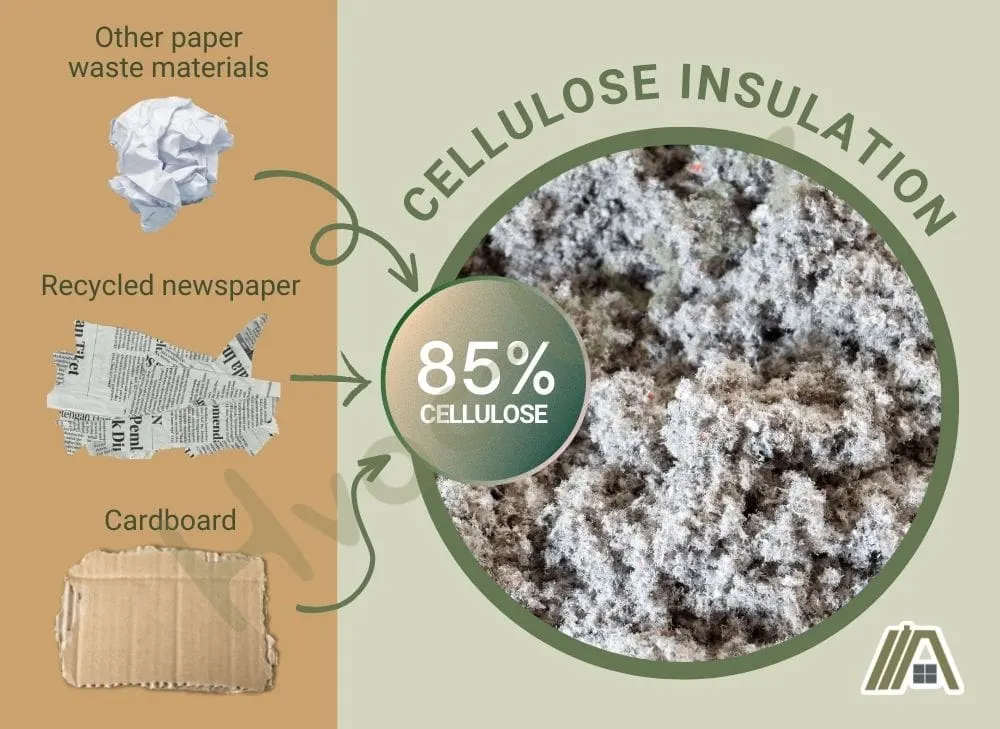

Up to 85% of cellulose is made up of recycled newspaper, cardboard, and other paper waste materials that are cut into tiny pieces before being fiberized.

This fiberized material is then treated (usually with borax or boric acid) in order to retard flame and put off any pests that would otherwise chew through it.

Cellulose is not a long-lasting insulation when compared to some of its competitors, but its lifespan is still a solid 20-30 years.

Appearance and Use

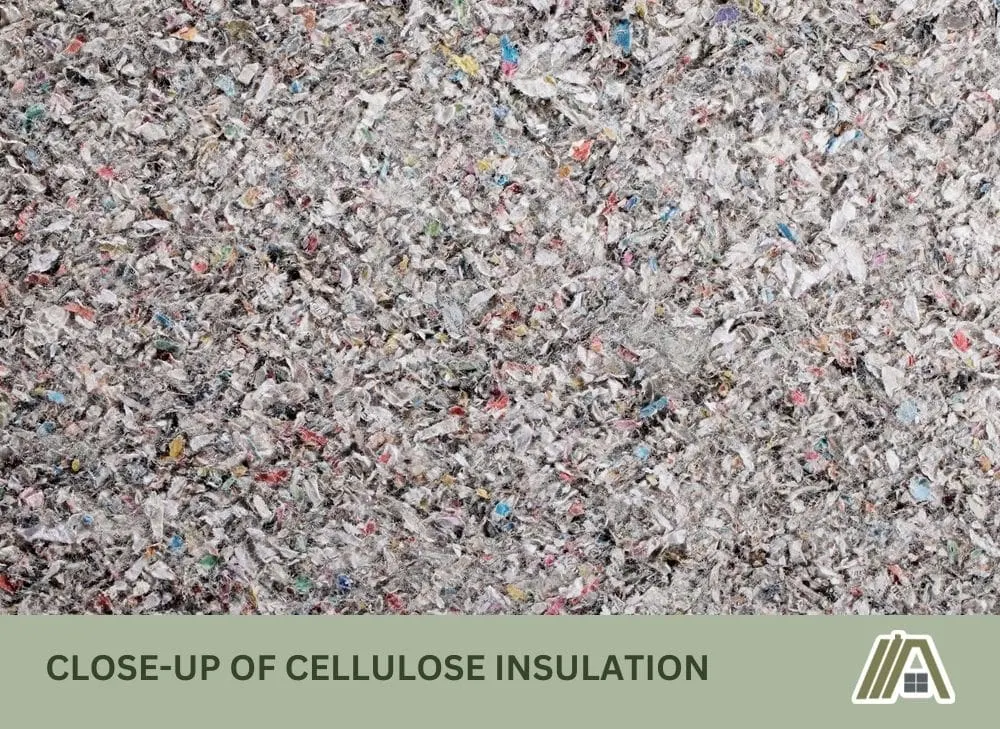

Cellulose insulation looks exactly like what it is—very finely shredded, pulverized paper materials (this is the easiest way to distinguish it from asbestos). If you imagined what a newspaper would look like after it’s been put through a food processor, you’d get the idea.

This means it’s primarily gray in color, with bits of color from ink sprinkled throughout. Overall, the texture of cellulose insulation is fluffy and almost wooly, like dryer lint or down feathers.

Cellulose insulation comes in two primary forms. The first is loose fill, which is mostly used in unfinished attic spaces.

The second form is dense packed, which is primarily used to fill in the spaces between walls and ceilings.

More recently, however, batted cellulose has also become available as an option for insulating walls. There are a few other types of cellulose insulation as well but they are not as commonly used.

Inherent R-Value of Cellulose Insulation

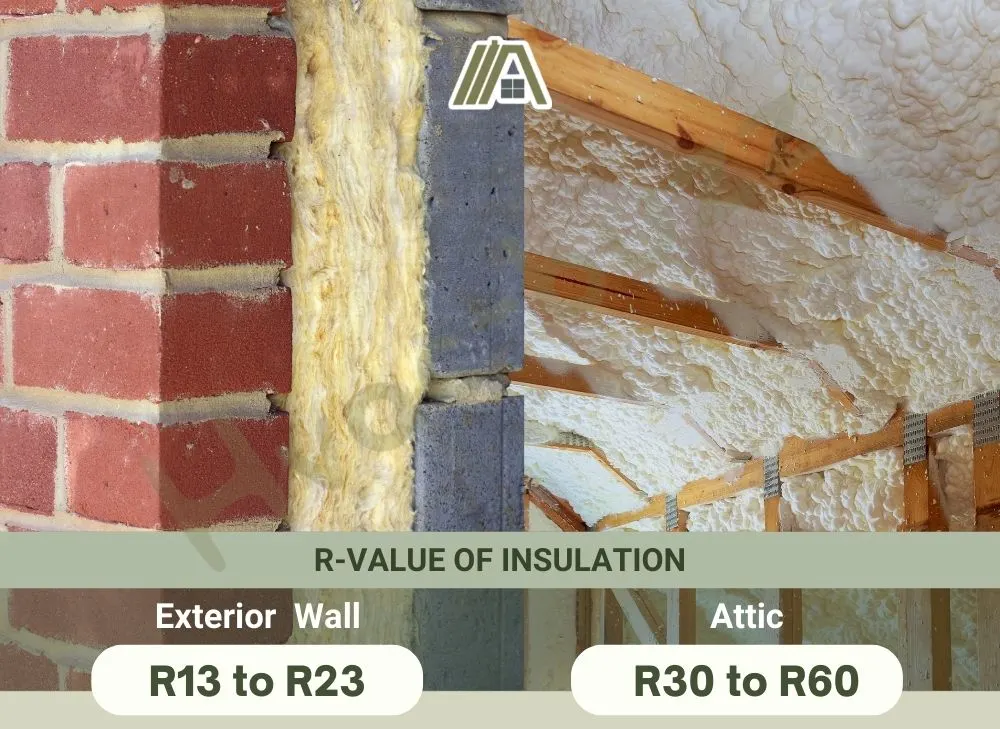

The R-value of insulation is one of the biggest things to consider when shopping around.

The R-value, or (thermal) resistance value, is a measure of how effective insulation is at resisting the flow of heat. In other words, it’s a measurement of how effective insulation is at, well, insulating.

Different parts of the home have different recommended R-values for insulation. Exterior walls for example may be fine at R13 to R23, while it is recommended that attics sit at between R30 and R60.

The R-value of cellulose insulation typically sits at between 3.2-3.8 per inch, depending on various factors like the form of cellulose insulation and how densely it is packed.

This is a high R-value when compared to other types of insulation, meaning you should need a lower thickness of cellulose to achieve the same R-value as other insulation materials might.

Thickness Guide

The thickness of insulation you will need to achieve various R-values will of course depend again on various things like what kind of cellulose you use, how densely you install it, and how it settles.

Since there are so many factors, let’s look at the R values of blown-in cellulose at its installed thickness for the sake of simplicity.

Each listed R-value is paired with the required thickness of cellulose in the chart below.

| Required R-Value | Inches of Blown Cellulose Insulation Needed |

| R30 | 9.1 |

| R38 | 11.4 |

| R40 | 11.8 |

| R49 | 14.5 |

| R50 | 14.8 |

| R60 | 17.7 |

Cost of Cellulose Insulation

Cellulose insulation may have a great R-value, but that comes at a cost! Cellulose insulation is one of the most expensive types of insulation.

Typically, a square foot of blown-in cellulose insulation will cost anywhere between $0.80 and $1.20, depending on the material you buy, how much space you’re filling, and who you hire.

The price may be well worth the benefits of cellulose to you, but this is just a reminder that cellulose only has a lifespan of 20-30 years. Replacement may be needed if you plan to keep your home for a long time, and that can increase your long-term costs!

Is It Easy to Install?

Cellulose insulation is generally quite easy to install. Blown-in cellulose is the most common type to use, and it’s a rather simple process, especially if you intend to fill an open space like an attic.

That said, installation of blown-in insulation is a two-person job that does require the use of a blowing machine. So, do-it-yourself installation may or may not be accessible to you.

Plus, while technically “easy,” cellulose insulation is messy and dusty. If cleanup factors into ease, that certainly lowers it!

If you intend to install blown-in cellulose, however, which is the most common, I would probably recommend hiring a professional.

Is Cellulose Insulation Dangerous?

The first potential danger you might consider with cellulose is fire, since it is a wood-fiber material.

However, as mentioned before, it is treated with borax, boric acid, or ammonium sulfate in order to make it fire-resistant and meet government safety regulations. In fact, it’s more fire-resistant than fiberglass.

That said, while cellulose insulation is not a fire hazard, it does have some risk. Cellulose may contain trace amounts of formaldehyde, chlorine, lead, and more.

Since cellulose does break down after 2-3 decades, it may release these harmful chemicals into your home as it deteriorates.

To be fair, we don’t have solid evidence so far that these trace amounts of chemicals are dangerous to the average person. However, if you have any respiratory illnesses or chemical fire retardant or ink sensitivities, then cellulose insulation could be a hazard—or at least an irritant—to you.

Furthermore, cellulose isn’t mold-resistant. In fact, if it gets wet, it takes forever to dry and become a breeding ground for mold! Now, if mold develops in your insulation, then that is a hazard.

Benefits of Cellulose Insulation

For starters, cellulose insulation is considered one of the most eco-friendly options, since it is primarily made from recycled, biodegradable material.

The material used to treat cellulose insulation also makes it quite unpalatable to any home pests. Many cellulose insulations are also treated with an acrylic binder on top of fire retardants, helping to slow down its loss of R-value over time.

Speaking of R-value, the R-value of cellulose insulation is higher than that of fiberglass, the most commonly used material, at approximately R3.2 and R2.2 per inch, respectively.

Lastly, it is quite lightweight and relatively easy to install, allowing it to settle well into hard-to-reach nooks and crannies throughout your walls and attic.

Drawbacks of Cellulose Insulation

Cellulose’s malleability and tendency to settle may help it to enter hard-to-reach areas, but it is also a problem. As cellulose settles, it becomes thinner in width and loses air pockets, reducing its R-value over time.

As mentioned earlier, cellulose has a tendency to retain moisture. If you ever have a leak, or experience humidity levels high enough to wet your insulation, it can take a long time to dry.

This can allow mold or rot to take hold, and mold in the home can cause severe respiratory issues if left to sit. Not only that, it’s hard to get rid of.

Last but not least, cellulose insulation is more costly than other insulation materials, like fiberglass. Plus, when you factor in its shorter life expectancy, the price discrepancy becomes even more apparent! For example, cellulose’s life expectancy of 20-30 years is nothing compared to fiberglass’ 90-100 years.

Sources

http://solar365.com/green-homes/insulation/cellulose-insulation-pros-cons

https://bct.eco.umass.edu/publications/articles/cellulose-insulation-a-smart-choice/

https://www.attainablehome.com/cellulose-insulation-pros-and-cons/

https://www.attainablehome.com/what-is-the-r-value-of-cellulose-insulation/

https://www.ecotelligenthomes.com/facts-about-cellulose-insulation/

https://www.energy.wsu.edu/documents/AHT_Inspection%20Attic%20Insulation.pdf

https://www.forbes.com/home-improvement/home/what-is-insulation-r-value/

https://www.greenbuildingadvisor.com/article/how-to-install-cellulose-insulation

https://www.greenfiber.com/uploads/documents/INS773LD-Cel-Pak-Extended-Coverage-Chart.pdf

https://www.homeadvisor.com/cost/insulation/install-blown-in-insulation/

https://www.homedepot.com/c/ab/insulation-r-values/9ba683603be9fa5395fab9091a9131f

https://www.homelogic.co.uk/cellulose-insulation-health-risks

https://www.reenergizeco.com/blog/replace-home-insulation/

https://www.thespruce.com/cellulose-insulation-basics-1821904