Ducting seems like an add-on compared to your main concern: the appliance. However, the ductwork of machines like clothes dryers is heavily regulated by the International Residential Code (IRC) to ensure the appliance operates properly and safely.

Incorrect ducting will cause you many problems, so it’s better to know what you are dealing with whether you are starting, are halfway through, or have finished ductwork that doesn’t seem quite right. Therefore, I have provided this guide on dryer ducts to help you understand what your ductwork should be and why it is important to comply with regulations.

The IRC stipulates the thickness, diameter, and maximum length of dryer ducts. Manufacturer instructions (for dryer or power ventilator) take precedence. If not specified, 35′ is the maximum length. This is reduced with the addition of elbows.

Building Codes Regulate Dryer Duct Dimensions

Section M1502.4 of the IRC contains the specifications for a dryer duct.

According to Section M1502.4.1, exhaust ducts must be:

- 0.0157” (0.3950 mm/No. 28 gage) thick, at minimum.

- 4” (102 mm) nominal diameter.

These are the foundations of the exhaust system. The minimum thickness is the lowest gage of ducting that can withstand the pressure your average dryer exhaust system creates.

Diameter is essential for airflow. A larger duct decreases the resistance against airflow but make it too big, and you risk the ducts being compressed in the small spaces through which they run. Therefore, this diameter has been established as the ideal (generally) size for effective airflow.

Section M1502.4.3 states that for transition ducts (flexible ducting that connects the dryer to the rigid ducts), it should be a single length that does not exceed 8” (2438 mm).

Section M1502.4.6 presents three methods of determining length:

- Specified length.

- Manufacturer instruction.

- Power ventilator.

Method 1: Specified Length

Dryer exhaust ducts cannot exceed 35’ (10 668 mm) between where it connects to the transition duct and where the exhaust terminates outdoors, as per Section M1502.4.6.1 (IRC).

Any fittings added to the ducting contribute to your maximum allowable duct length. Fittings are the elbows or bends that direct the ducting to the outlet.

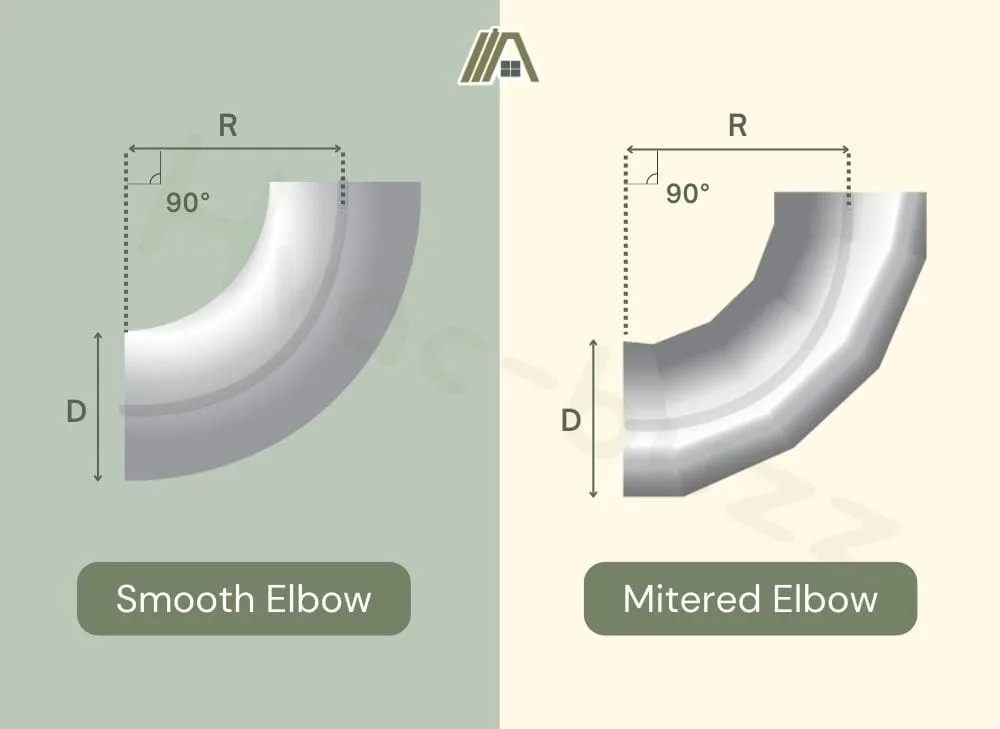

Before moving on to the numbers, I want to distinguish between smooth and mitered elbows. Smooth elbows are a whole, curved fitting. Mitered elbows are separate pieces cut at angles and put together.

| Elbow | Consumed length | Maximum duct length with the fitting |

| 4” radius mitered 45° | 2’ 6” | 32’ 6” |

| 4” radius mitered 90° | 5’ | 30’ |

| 6” radius smooth 45° | 1’ | 34’ |

| 6” radius smooth 90° | 1’ 9” | 33’ 3” |

| 8” radius smooth 45° | 1’ | 34’ |

| 8” radius smooth 90° | 1’ 7” | 33’ 5” |

| 10” radius smooth 45° | 9” | 26’ |

| 10” radius smooth 90° | 1’ 9” | 33’ 3” |

Why Fittings Reduce the Allowable Length

Airflow through ducting is determined by velocity pressure (momentum) and static pressure (resistance). The first is the force behind the air, moving it forward, while the second is how the air is slowed as it makes contact with the duct surface.

The more bends and curves you have in your ducting, the more it negatively impacts airflow. When air cannot move in a straight line, it is slowed because it offers more resistance and decreases velocity pressure.

The point of exhaust systems is to remove substance particles and moisture with the air. In a dryer exhaust system, you are removing lint, VOCs, and humid air. The slower the air moves, the more it will deposit on the way.

You will also experience dripping or leaking problems as slow air in the duct has more time to cool and create condensation.

Lint gathers up as it is dropped by the airflow or sticks to condensed water droplets in the vent instead of being exhausted. This is dangerous as a fire hazard.

Why Longer Runs Are Allowed With Wider Ducts

It is a balancing act regarding ducting and the pressures that influence air in the ductwork.

Longer duct runs are permitted with wider ducts because the wider tubing decreases the amount of static pressure on the air.

This means that less of the air molecules come into contact with the inner surfaces of the ducts and more molecules continue on their laminar flow course, resulting in less slowing.

Why Mitered Elbows Are Limited to 4” Ducts

There is a reason that the inner surface of exhaust ducts is supposed to be smooth. A smooth surface provides less friction (or static pressure) to the air moving through the line.

Mitered elbows are created using small, angled sections of tubing that are welded together. That doesn’t sound very smooth to me!

On top of this, an elbow is used to bend the direction of ductwork, which means you are looking at a lot of resistance for the forward flow of air in the ductwork.

So, mitered elbows are limited to the smallest duct size. The size that is considered most appropriate for the majority of exhaust ducting, where the velocity pressure is enough to overcome the bend and the surface of the elbow.

Why Elbows Are Listed for Ducts Over 4”

The fact that the IRC lists elbows for ducting over 4″ in diameter seems to contravene Section M1502.4.1, which says the ducting must be 4″ wide. However, this is a nominal figure, which means that it may not actually correspond to the actual dimension.

Consider that, due to prioritization, you should use the duct width that the manufacturer recommends or allows. Using the term ‘nominal’ means that there is actually no contravention.

Some exhaust systems may call for different ducting, and you need to know how this length is affected as well.

Downsizing inappropriately can negatively impact the system’s exhaust capabilities, noise levels, and energy usage.

Since you might need wider ducting for a longer run, this information can be helpful. However, keep in mind that there is a limit to this modification, and you should adhere to the manufacturer’s directions as closely as possible.

Method 2: Manufacturer Instructions

Wherever available, instructions from the manufacturer about the duct dimensions and installation should take precedence over the IRC, as stated in Section M1502.4.6.2.

You will find this information for duct size and length in the installation manual for the dryer. Some brands may have this available for download from their product page, or you may be able to search for the PDF online.

This may sound risky for the IRC to say, but some parameters make it all reliable.

If you are using the products that the IRC approves of, you can trust that the installation is safe. Any trustworthy manufacturer will provide the best input for duct efficiency and appliance function. The manufacturer is, after all, the one who has designed and worked with the appliance. They are the expert.

This will look like a rating code. If your dryer is listed with a UL, ANSI, CSA, or ANCE code, this shows that it is rated by a safety organization and is approved by the IRC for safety and function standards.

If you cannot find the dimension information for the product with the installation guide, the IRC requires compliance with the first method.

Method 3: Dryer Exhaust Power Ventilator

According to Section M1502.4.6.3 of the IRC, dryer exhaust duct length can be determined by manufacturer instructions for a dryer exhaust duct power ventilator (DEDPV).

A power ventilator is a device that you install in your ducting system to assist airflow in ducts that are necessarily longer. For example, sometimes, you don’t have the space to vent the dryer on the shortest path, or the dryer needs to go in the middle of the house.

Whatever your situation, you may just need a few extra feet, and this device helps push air through the ducts.

It is essential to know that booster fans and power ventilators are NOT the same. DEDPVs are allowed by the IRC, but booster fans are prohibited. So, ensure you are looking at a regulated (listed) appliance.

The power ventilator is intended to help where length cannot be avoided and is not a good “convenience” solution to avoiding extra mess and fuss.

This is another machine that moves air. It can fail or break, meaning your dryer isn’t exhausting correctly or efficiently. If you need a DEDPV, make sure you check it often.

Sources

https://www.ccohs.ca/oshanswers/prevention/ventilation/ducts.html

https://forum.wordreference.com/threads/mitered-vs-smooth.3912571/

https://vicsairconditioning.com/blog/the-importance-of-proper-duct-sizing