Keeping your home’s temperature under control is a key element to focus on when building it, especially if you are situated in parts of the world that experience extreme temperatures. Insulation can lower your heating and cooling costs and is more eco-friendly.

There are many types of insulation to choose from, but fiberglass insulation is one of the most common. Here is all you need to know about fiberglass insulation and how to install it.

Fiberglass insulation looks like long, thin, interwoven glass fibers, typically colored pink, green, or blue. It’s a raw/synthetic mixture with an inherent R-value of 2.2-3.4 and a cost of $0.5-1.2, depending on the form. Fiberglass comes as loose-fill, batts, rolls, and boards. It can be dangerous.

What Is Fiberglass Insulation?

Fiberglass insulation is one of the more traditional forms of insulation found on the market today.

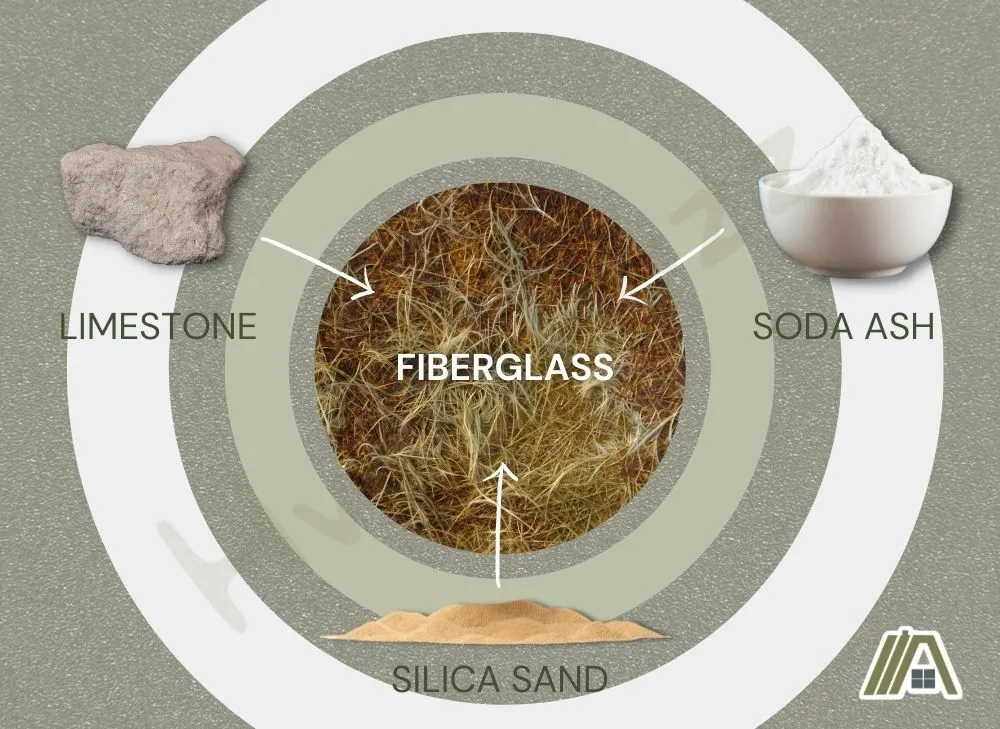

This type of insulation is made from a mixture of raw and synthetic materials, such as silica sand, limestone, and soda ash. These materials combine to create separate thin glass fibers that can be used in different forms.

Fiberglass insulation can last up to 100 years if it is untouched, but this isn’t usually the case. The life span of your insulation can be influenced by various factors like water damage and physical damage.

It is rare that your insulation will reach the ripe old age of 100 as the natural degradation of the product occurs, and it may not perform as effectively as it once did initially.

Appearance and Use

Fiberglass insulation looks like hundreds of interwoven long and thin glass fibers. These fibers are either compacted together to create thick flat pieces called batts or into larger rolls. Blown-in fiberglass insulation is also a popular form.

One form that is the least common is fiberglass boards, which can be rigid or semi-rigid, depending on the density of the board.

Batts are usually used between wall studs and are stapled in place. Rolls and fiberglass boards can be used between walls as well as ceiling joists. Blown-in fiberglass is more for those hard-to-reach crevices that most are not able to get to, like around pipes and attic spaces.

Fiberglass insulation also comes in various colors, including but not limited to pink, green, and blue. However, these colors are merely only used to identify the manufacturer of said insulation and don’t really have any other purpose.

Inherent R-Value of Fiberglass Insulation

Apart from the cost of the insulation, the R-value is one of the most important characteristics you need to consider when purchasing your insulation.

The R-value is a measure of how well an insulating material can resist heat flow. In theory, the greater the R-value, the greater the ability of the insulation material to keep heat in. The R-value is also proportional to how thick or how dense your insulation is.

Blown-in fiberglass has an inherent R-value of 2.2-2.7, and the batts are 3.1-3.4.

Fiberglass insulation can be used in many forms and in different parts of a home, but some places require greater R-values in comparison to others.

So, you may need to consider not only the form of insulation to use but also how much heat needs to be contained in that area and how thick the insulation needs to be to achieve this. For example, the R-value for ceiling or attic insulation may be higher than for wall insulation.

Thickness Guide

| R-value | Batts and roll (inch) | Blow-in (inch) |

| R30 | 8.25 | 10.25 |

| R38 | 10 to 10-1/4 | 12.75 |

| R40 | 11.30 | 12 |

| R49 | 14 | 16.25 |

| R50 | 15 | 15-19 |

| R60 | 19-22 | 16-20 |

Cost of Fiberglass Insulation

If you are money-conscious and need something affordable, then being at fiberglass insulation station is where you want to be.

It is one of the most affordable insulations on the market today, costing around $0.64 and $1.20 per board foot if you are installing batts and around $0.50 and $1 per board foot if you are blowing in the fiberglass.

These fiberglass cost estimates exclude labor for installation. The cost for installation of batts can range between $1.87 and $2.97 per board foot.

It is still more affordable than its other competitors, like spray foam insulation, which can cost around $1 to $5 per square foot.

Is It Easy to Install?

The installation process isn’t too difficult.

When it comes to installing fiberglass batts, you would just need to take your batt pieces and lay them in the gaps in your walls. And because of the type of material fiberglass insulation is made from, it lays quite rigid (yet very flexible) and fills gaps in walls quite efficiently.

If you are installing insulation on ceilings, you will have gravity against you and need to staple them to the ceiling boards with the help of a friend.

Rolls are also DIY as you would just need to roll the insulation into the required spaces and are not in pieces like batts are.

However, blown-in fiberglass insulation is a little harder as you need to rent a blowing machine and feed fiberglass fill into the machine. You will need one person to switch on the machine and manage it while the other fills the gaps by directing the hose.

Is Fiberglass Insulation Dangerous?

Due to the nature of the material, it can be very dangerous to handle and you need to take precautions. The thin glass fibers are easily broken and can break up into smaller particles and exposure to these are what causes discomfort and is an irritant.

Should it come in contact with and penetrate the skin, the fragments lodge themselves in the skin causing a rash that can lead to flaky, red, and irritated skin with blisters. The deeper the penetration, the longer the exposure and the thicker the fibers the more severe the symptoms will be.

Fibers may also land up in the eyes and lungs causing further irritation. You can prevent these outcomes by simply wearing protective clothing such as:

- Protective goggles with side shields

- Rubber gloves.

- Loose or disposable clothing.

If you do come into contact with fiberglass, wash your skin and pat down with a towel. Place some tape over the glass fibers on your skin and peel the tape off. Repeat this until all the fibers have been removed.

You may experience more skin irritation if dealing with batts and rolls as it’s a very hands-on job. However, blown-in insulation may just land up everywhere as these fibers are small and everywhere, especially in your eyes.

Benefits of Fiberglass Insulation

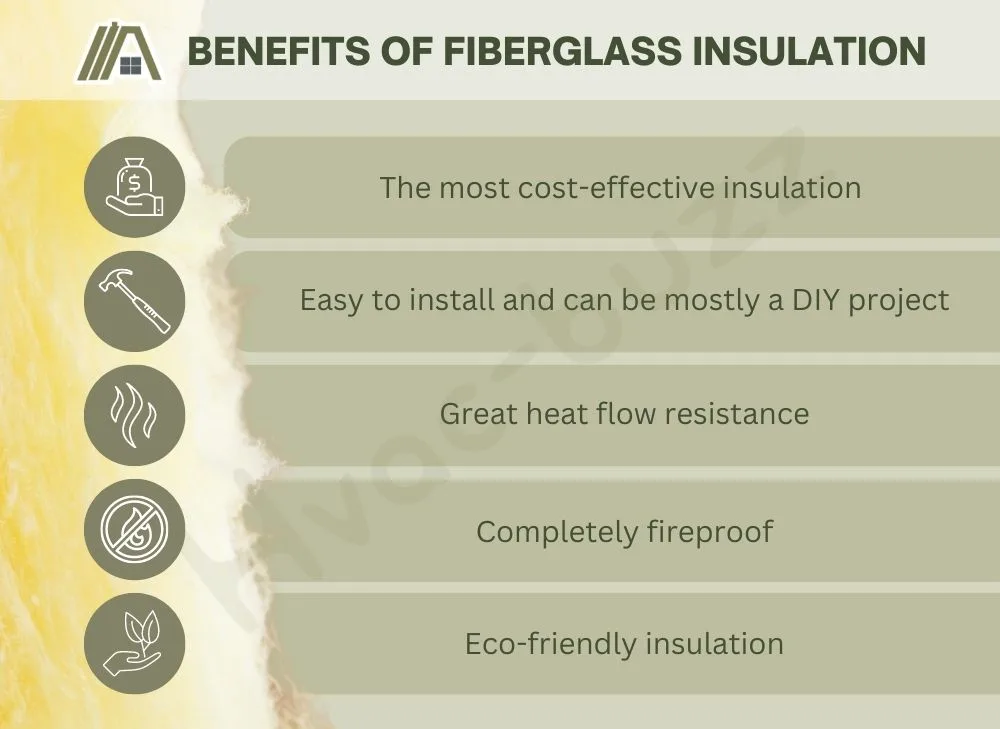

- The most cost-effective insulation in comparison to the more expensive insulations like spray foam insulation.

- Easy to install and can be mostly a DIY project. No professional help is needed to install this insulation, saving you some pretty pennies.

- Great heat flow resistance as glass is not a good conductor of heat.

- Like mineral wool insulation, fiberglass insulation is completely fireproof and can be used safely around electrical wiring.

- Eco-friendly insulation as most of it is made from recycled glass and sand. Thus, it is quite a sustainable type of insulation that’s not harmful to the environment.

Drawbacks of Fiberglass Insulation

- Working in direct contact with toxic materials. It can cause quite severe dermatitis when in contact with skin and also cause eye irritations. Mineral wool is much safer.

- It doesn’t act as a vapor barrier, allowing moisture to infiltrate your home. You may need to add a film to the insulation, which can come at an extra cost. Spray foam, however, is a vapor barrier on its own.

- Unlike spray foam insulation, fiberglass does lose its shape over time and starts to settle and expose gaps allowing air to move freely. This decreases the R-value of the insulation and will continue to do so over its lifespan.

Sources

https://www.retrofoamofmichigan.com/blog/fiberglass-insulation-material-ingredients

https://www.buildwithrise.com/stories/fiberglass-insulation

https://pricewiseinsulation.com.au/blog/insulation-batts-vs-rolls/

https://inspectapedia.com/insulation/Fiberglass_Insulation_Identification.php

https://advantagehomeperformance.com/insulation/insulation-materials/

https://www.tidewaterinsulators.com/blog/what-does-insulation-look-like

https://www.seacoastonline.com/story/news/2001/03/18/how-safe-is-your-basement/51302139007/