Laying ductwork is not my favorite job, particularly if it’s a retrofit job and the ceilings and walls are already in place. Using flex ducts makes the work easier (it’s also cheaper), so ideally, I’d like to use it for all my ventilation systems. However, safety always trumps convenience when it comes to construction.

The building codes to which we have to adhere explicitly control the type of duct that can be used for range hoods; it’s not left up to our discretion. However, the benefits of the ducts that are permitted for use make any extra effort worth it.

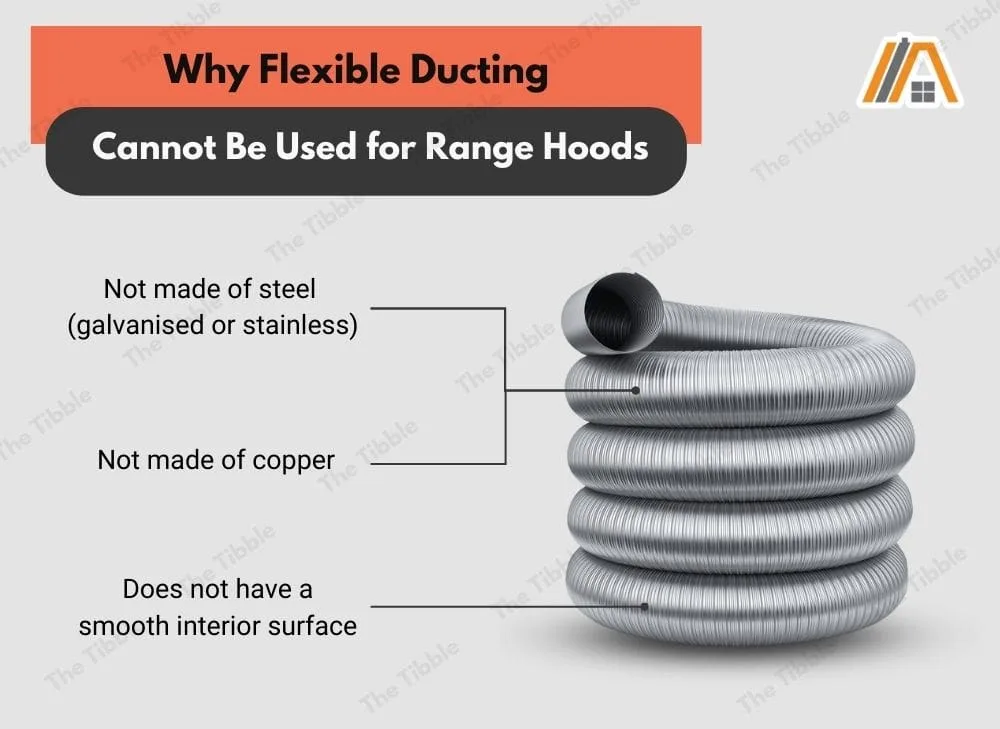

Flexible ducting cannot be used for range hoods. Building codes require these ducts to be made of steel or copper and they must also have a smooth surface. Flexible ducts are made from aluminum and/or PVC and they have ridged inner surfaces. The rules exist for the function and safety of range hoods.

Flexible Ducting Cannot Be Used for Range Hoods

Building Codes

If you are ever looking for the codes controlling range hood construction/installation, you can start with the International Residential Code (IRC), Section M1503.

This code is adapted on a local level, but the coordinates and layout are similar, so this will still help you to find the information in state-specific codes.

Duct material is covered in Section M1503.4 of the IRC. But there is also a key piece of information about the characteristics of allowable ducts in Section M1503.3.

From these two sections, we know that range hood ducting must be made of steel (galvanised or stainless) or copper, and the duct has to have a smooth interior surface. Flexible ducting fails on both counts.

Firstly, flexible ducts are typically made of aluminum and/or plastic. Secondly, they are flexible because of their concertina construction, which creates ridges along the inner surface, so it is not smooth.

We will shortly get to why these requirements exist, but I first want to talk about manufacturer instructions.

Manufacturer Instructions

In the manual for your range hood, the manufacturer will specify what type of ducts you can use. This has two implications.

One, the IRC defers to manufacturer requirements because they know the individual product the best. The product is only available for sale once it meets certain standards, so the IRC is confident that the correct information will be provided by the manufacturer.

Two, if you go against the manufacturer’s instructions, you will void your warranty.

Why do I mention this? Well, you will be hard pushed to find a range hood manufacturer that does not either prohibit flexible ducting or specify rigid metal ducting for use with their appliances.

Why the Material Matters

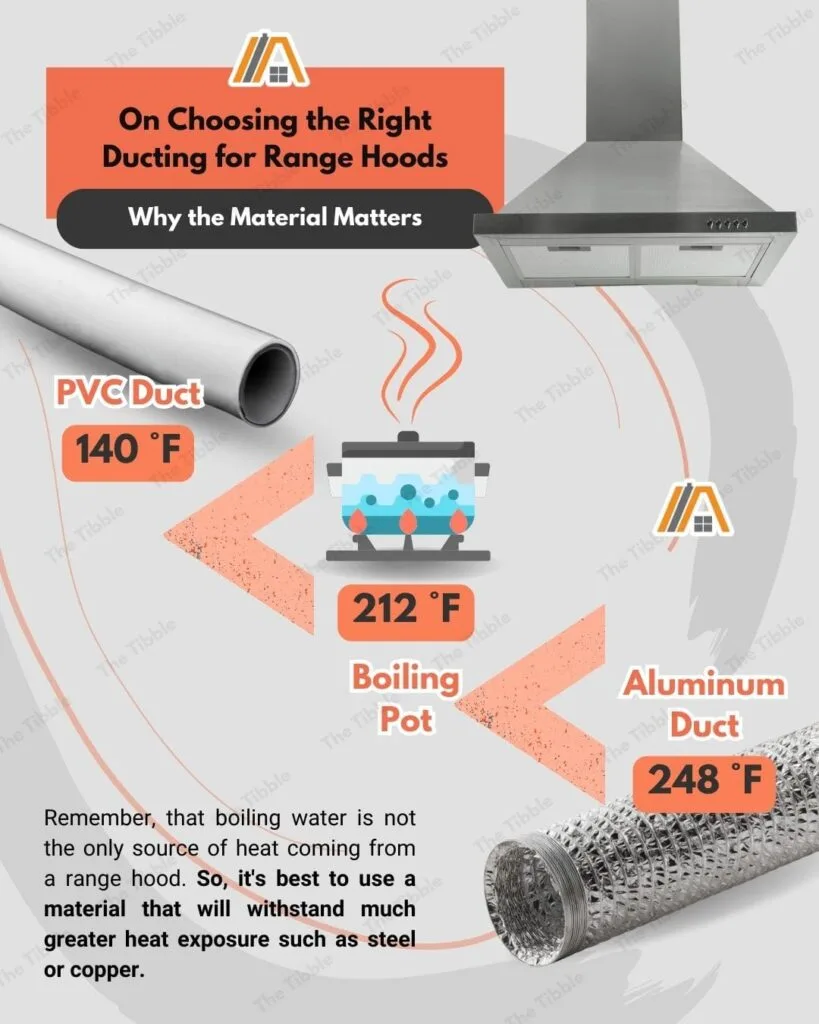

Range hoods carry hot air, so the ducting used cannot be susceptible to heat damage.

Aluminum ducts can have a heat resistance as low as 120 °C, which is about 248 °F. PVC (the most common type of ducting plastic) has a heat resistance of about 60 °C or 140 °F.

Water from a boiling pot becomes steam at 212 °F. This exceeds the heat tolerance of PVC and comes dangerously close to that of aluminum ducting.

Remember, that boiling water is not the only source of heat coming from a range hood. So, it’s best to just use a material that will withstand much greater heat exposure.

When these materials overheat, they can deform or break, which slows and can even prohibit proper exhausting of contaminated kitchen air.

Aluminum ducting is also readily damaged because it is so thin and weak. Any tears or punctures in the material will compromise the function of the whole system.

The exhaust rate of range hoods is relatively high because the rate is determined by the size of the range, and normal homes are starting to commonly use commercial-sized ranges.

Greater exhaust rates put more pressure on ducting than smaller ones, so the material has to be durable enough to withstand these forces.

Why the Surface Must Be Smooth

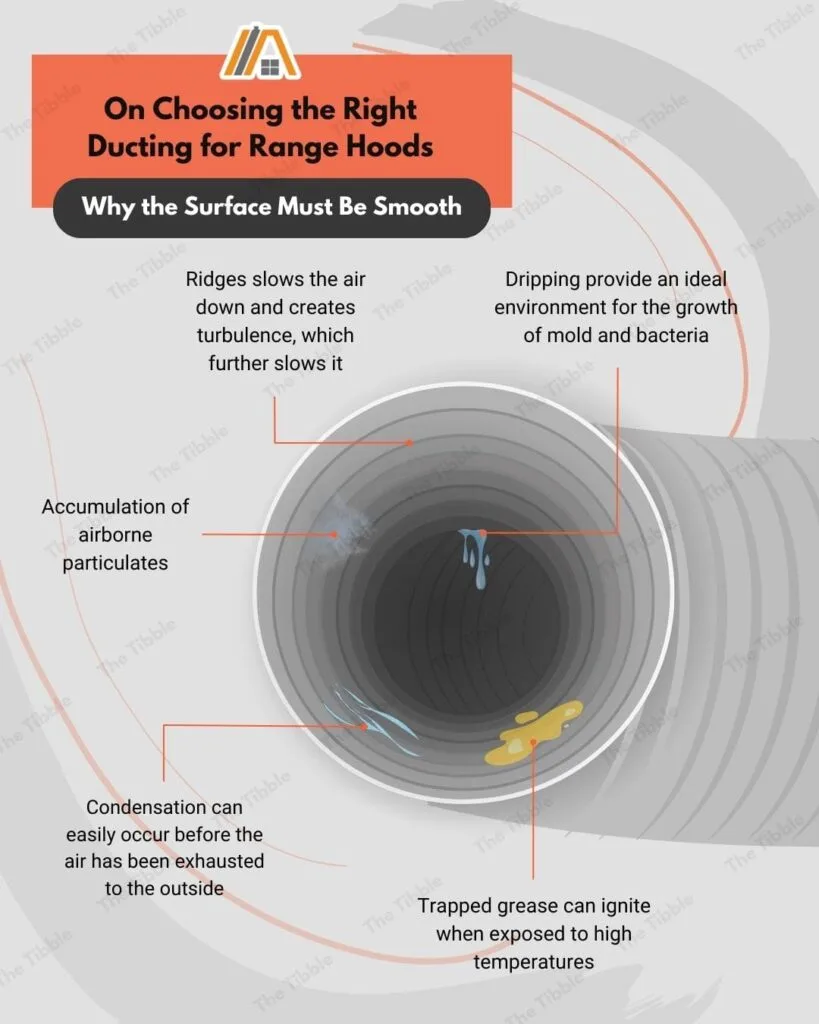

In order to understand why the inner surface of range hood ducts must be smooth, we need to consider what is being removed by the ventilation system.

Hot air is only one aspect of this. Cooking fumes, airborne particulates, grease, and odors are also carried out by the exhaust system.

The ridges in a flexible duct would provide ideal spots for the accumulation of these things, preventing them from actually being exhausted, and providing them with the chance to re-enter the kitchen as soon as the range hood is turned off.

Ridges also increase the static pressure in a duct, which is more commonly known as friction. Friction slows the air down and creates turbulence, which further slows it.

The air takes longer to leave the ducting and condensation can easily occur before the air has been exhausted to the outside.

Condensation in range hood ducts can cause dripping and provide an ideal environment for the growth of mold and bacteria (don’t forget that all the trapped food and grease will be great sources of nutrients for these microbes).

Trapped grease is really sticky and it will trap and attract dirt, bacteria, and mold as well. More pertinent to the collection of grease is the fact that it can ignite when exposed to high temperatures (like those provided by the hot, exhausted air).

Grease fires are notoriously hard to extinguish. In addition, a fire in the ductwork can go unnoticed for long enough to allow it to spread through the house. This is also made so much easier by the fact that the ducts run like a convenient channel through the house.

If your home is affected by a grease fire, originating in the range hood ducts, your insurance coverage is jeopardized by the presence of flexible ducting because it is not code compliant and most likely against manufacturer specifications.

You eliminate a lot of these issues but just smoothing the interior surfaces of the ducts, which is why rigid ducts are considered to be the only sufficiently low-risk option for range hoods.

Maintenance Considerations

It is technically possible (although not permitted) to use flexible ducting for range hoods. However, your maintenance regimen will have to be intense and you will, in all likelihood, have to replace the ducts fairly regularly.

All the money you’d save on the cheaper flexible ducts and more will be used for cleaning and replacement.

Beware of range hood vent kits that come with flexible ducting, like this one (amazon link). Even if the intention is for the flex duct to connect the range hood and rigid ductwork, you should be wary. I cannot find any allowance of this in the IRC.

Misconceptions About Rigid PVC Ducts

There is an exception to the steel or copper only rule set out in Section M1503.4. This exception covers when rigid PVC ducts are allowed to be used.

A common mistake is to say that this is an exception for range hoods. However, if you look at the wording of the code properly, you will see that the exception is for a specific type of exhaust system, which is different to a range hood.

Rigid PVC ducts can only be used with cooking appliances with downdraft exhaust systems. These are located below or behind the range, unlike range hoods, which are located overheard.

What Type of Duct Is Best for Venting a Range Hood?

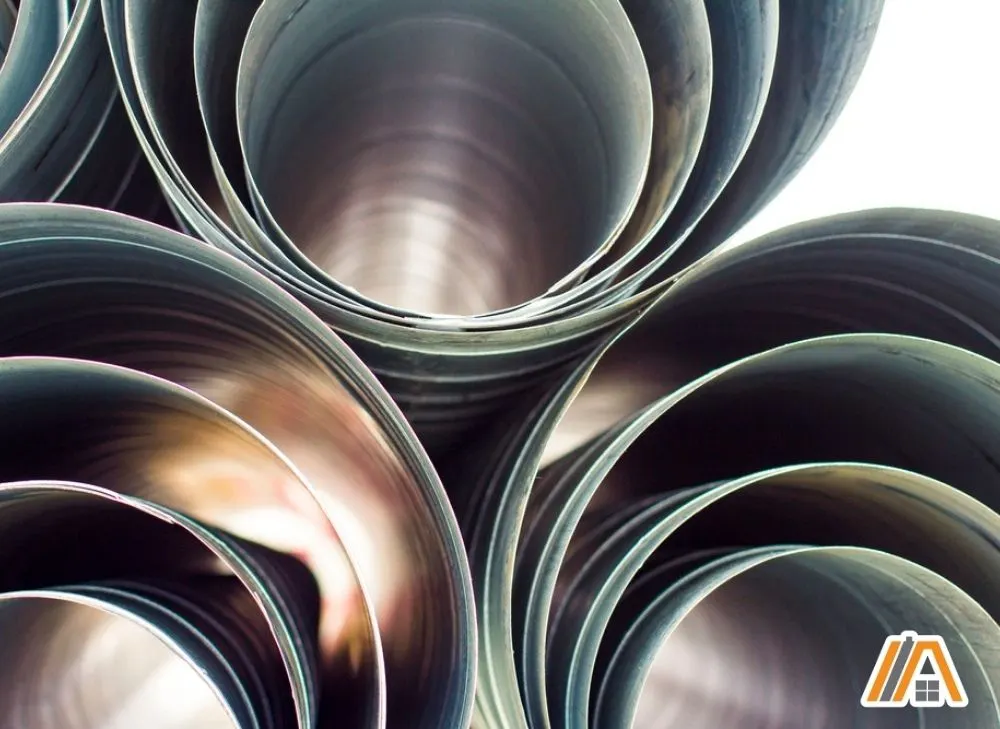

Rigid stainless steel or galvanized steel is the best option for range hoods.

These metals are mechanically durable (the can withstand pressure and action that might penetrate or tear a weaker materials) and they have extremely high heat tolerance.

The rigidity of the metal used means that the inner surface can be (and is) smooth. Laminar airflow is promoted and turbulent airflow is minimized, allowing the most efficient function of the range hood.

The lack of ridges means that all the potentially harmful and/or hazardous substances being exhausted are less likely to be deposited and accumulate in the ducting.

Overall, this reduces the risk of dripping, mold and bacterial growth, as well as grease fires.

Maintenance is also easier and the ductwork will last longer.

Rigid metal ductwork also enables you to get away with longer duct runs because they do not slow the movement of air like flexible ducts do.

You don’t want to make the run any longer than necessary, but using rigid metal ducts can mean having your range hood terminate through the roof as opposed to the side of the house, where it is more visible.

Compliance with building codes means that you avoid fines or expensive replacement of the whole duct system to become compliant.

You also keep your warranty intact and, in the event of any insurable risk occurring, your insurance provider will have one less reason to try get out of paying.

Do You Need a Range Hood at All?

Local codes can differ when it comes to whether or not range hoods are required (you can read my articles for North Carolina, California, Ohio, Ontario, Colorado, and Florida). However, they all stipulate that if you have a vented range hood, it has to conform to the ducting rules.

So, if it’s just not possible for you to use rigid metal ducting, then you might consider forgoing a range hood altogether or opting for a ductless version, which is allowable under compliance conditions.

You do need to consider the benefits of range hoods that you will be giving up and/or the limitations of ductless models before you make your final decision.