Whether you are looking for efficiency or décor or are trying to check the code compliance of your new home, you need to know a few things about enclosing a furnace.

Enclosing a furnace must be done according to strict regulations provided by the building code. This is because you are risking a lot in terms of the gaseous emissions, but enclosure can be useful when correctly done.

Furnace enclosure is permitted under the specifications stated in the IRC to prevent it from becoming dangerous. Enclosures for furnaces must be constructed to provide sufficient combustion air, be accessed appropriately for maintenance, and have appropriate clearances.

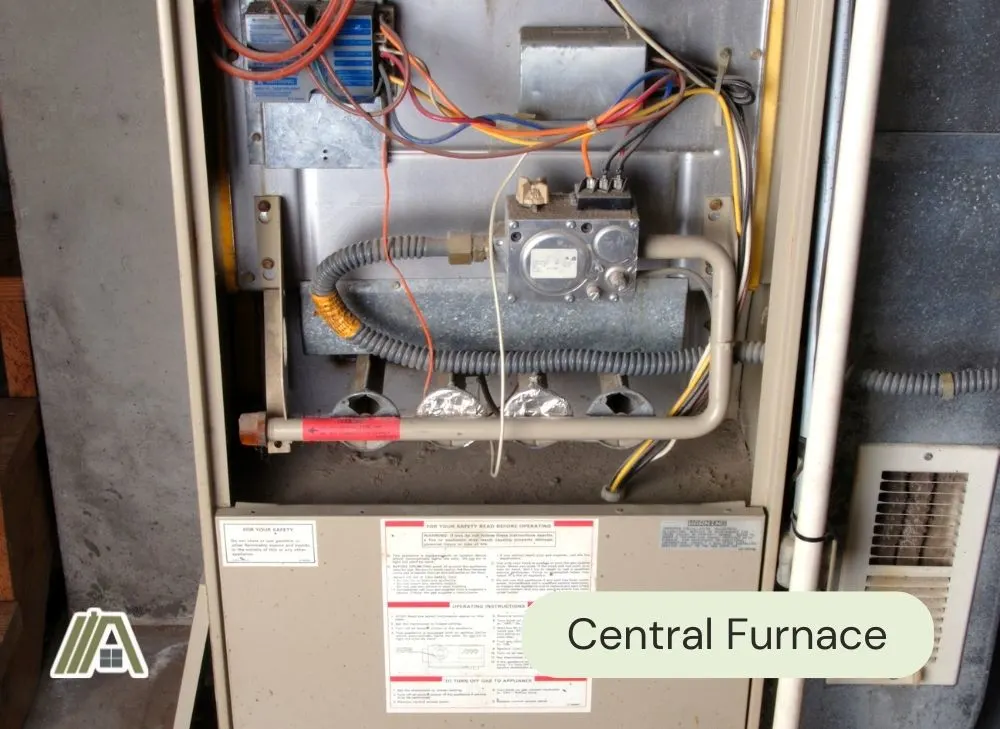

Benefits of Enclosing Central Furnaces

When people talk about enclosing a furnace, they generally mean a central furnace. However, we will look at the other two types at the end of the article, just in case.

A code-compliant enclosure that is well-installed can improve the efficiency of combustion in your furnace.

By supplying combustion air to the furnace (which you need to do when it’s enclosed), the furnace is better at heating without as much effort, giving you better heating levels and decreased energy use.

You also have the benefit of an enclosed furnace being hidden. You can make the outside of the enclosure far more aesthetically pleasing than you ever can with the furnace itself.

Central Furnaces Can Be Enclosed Conditionally

Because of the benefits, you will be glad to learn that furnaces can be enclosed as long as certain conditions are met to avoid the risks associated with enclosing the appliance.

It must comply with the clearance, access, and airflow requirements laid out in the International Residential Code (IRC).

These aspects are essential to:

- Keep your furnace at an appropriate distance from flammable materials to prevent fires.

- Allow you to inspect and maintain your furnace to keep it in working order and to prevent dangers associated with a malfunctioning or failing appliance.

- Ensure there is enough air for the combustion process of your furnace and to vent out combustion by-products that can be harmful.

Clearance Requirements for Furnace Enclosure

Furnace clearances are crucial for fire safety and accessibility, so I have written a furnace clearance guide covering what the IRC says and what several brands require.

Per Section M1402.2 of the IRC, central furnace clearances must be done according to the manufacturer’s instructions and the listing of the appliance.

The manufacturers dictate furnace clearances for a listed and approved product. Furnace orientation can influence these clearances (furnaces in crawl spaces will likely need to be installed vertically).

On the whole, furnaces require minimal clearance distances; however, manufacturers recommend you comply with the service clearance (24″) for the control side of the appliance.

In addition, most central furnaces don’t have floor clearances and are permitted to sit directly on wood and non-combustible flooring (check the installation manual).

Access

General Access

According to Section M1305.1 of the IRC, the general access requirements for an appliance (a furnace, in this case) are:

- The furnace must be in a place that is accessible for inspections, servicing, repairs, and replacing of the unit or part thereof.

- This must all be possible without removing a permanent construction (i.e., break through a wall), other appliances, or the furnace’s connections (pipes and ducts).

- This section also requires a working space in front of the control panel/side of 30 x 30” (762 x 762 mm).

Alcove Access

When installing a furnace in an alcove (or similar room), Section M1305.1.1 states that:

- The space must be accessible through a door or opening, with a clear passageway big enough to remove the largest appliance through it (the furnace, if it is the only appliance there) while being a minimum of 24” (610 mm) wide.

- There must be a level service space at least 30” (762 mm) deep and as tall as the furnace.

- There must also be at least 30” (762 mm) in front of the furnace when the door to the space is open.

Underfloor Access

Access to the furnace where installed under the floors is as such, according to Section M1301.3:

- The underfloor space must be accessible by an unobstructed passageway at least 30” (762 mm) high and 22” (559 mm) wide.

- The passageway must not measure more than 20’ (6096 mm) along the centerline from the appliance to the opening.

Exception: passageway length is unlimited if it is unobstructed and at least 6’ by 22” (1829×559 mm) for the full length.

- There must be a level service space of at least 30 x 30” (762 x 762 mm) on the side the appliance is serviced from, i.e., the control side.

- Passageways deeper than 12″ (305 mm) shall be reinforced by concrete/masonry lining that extends 4″ (102 mm) above the grade.

- The opening in a lined passageway (rough-framed access opening) must be at least 22 x 30” (559 x 762 mm) and must be big enough to remove the largest appliance in the space.

Airflow Requirements for Furnace Enclosure

According to Section G2407.2 of the IRC, the enclosure cannot interfere with proper air circulation that the appliance requires for combustion and ventilation.

Airflow requirements are specific to furnaces that use fuel for heating, as a certain amount of air is required in the combustion process that converts fuel to energy.

Ensuring Sufficient Indoor Combustion Air

Indoor combustion air is addressed in Section G2407.5 of the IRC.

Furnaces look at how many Btus the appliance uses per hour to increase temperature by 1 ℉. This ranges between 40,000 and 200,000. First, you will need to locate the manufacturer label for your furnace.

Btu input ratings refer to how much heat an appliance generates using its fuel, while the output rating refers to the heat it provides to your home. We need to know the input for this calculation since combustion air is related to fuel usage.

Once you know the Btu/h, you can determine how big the enclosure will need to be to provide sufficient combustion air. The volume of indoor combustion air required can be determined by two methods.

Standard Method (Section G2407.5.1)

The minimum volume will be 50 ft3 per 1,000 Btu/h (4.8 m3/kW).

This method is relatively straightforward and requires little as far as calculations.

The US and the UK use British Thermal Units (Btu; the amount of power needed to heat 1 lb of water by 1 ℉) as their power unit, while Europe and other countries use kiloWatts (kW).

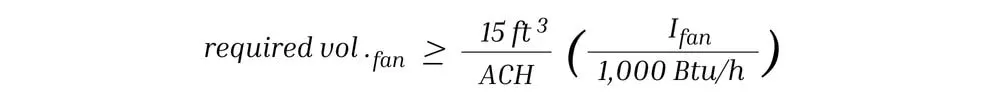

Known Air-Filtration-Rate Method (Section G2407.5.2)

Sometimes the air infiltration rate in the house is known, depending on your furnace venting category (see label and manual). The two most common categories are as follows, with the appropriate equation for the minimum volume of indoor combustion air:

- Category I (negative/neutral pressure, non-condensing, draft inducer fan) is fan-assisted:

- Where:

- ACH = air change/hour (decimal expression of % of volume of space exchanged/hour).

- ACH is limited to 0.60 or less for this calculation.

- Ifan = input Btu/h.

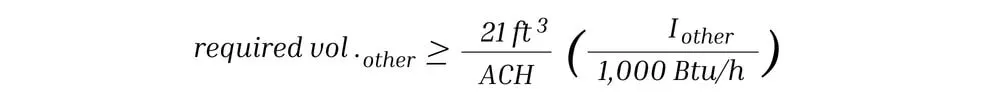

- Category IV (positive pressure, condensing) is non-fan assisted:

- Where:

- ACH = air change/hour.

- ACH is limited to 0.60 or less for this calculation.

- Iother = input Btu/h.

Openings

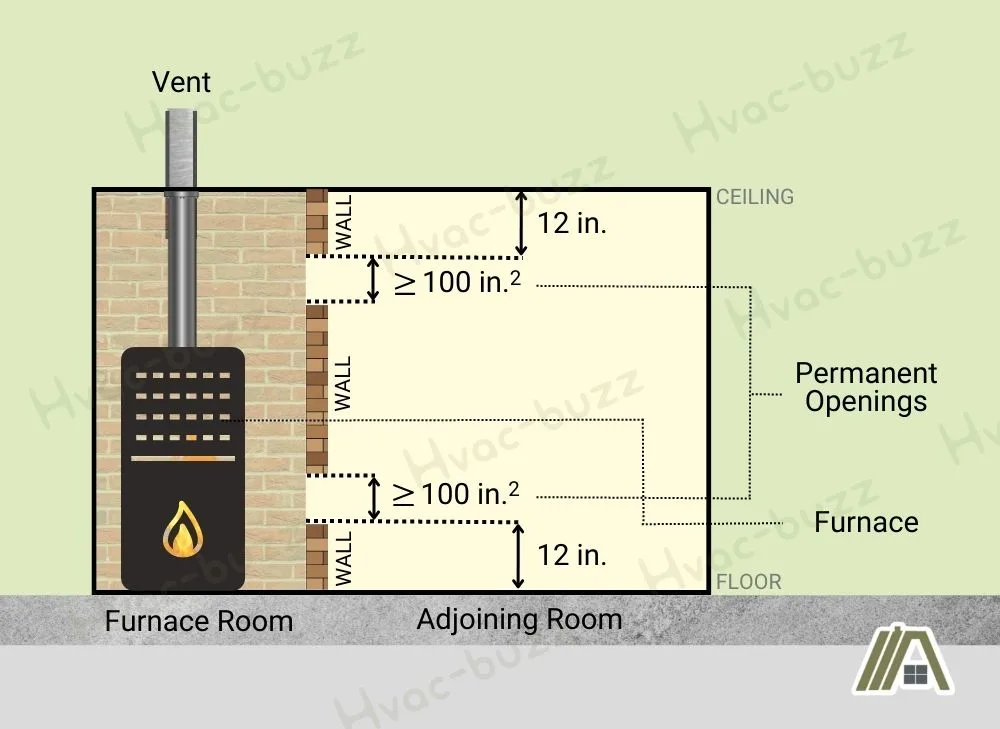

Section G2407.5.3 of the IRC covers “combining spaces”, which regulates the openings used to connect indoor spaces for indoor combustion air supply.

Openings connecting same-story spaces (Section G2407.5.3.1) must have a completely open (free) area of 1 in2/1,000 Btu/h (2,200 mm2/kW) and you need to account for the total Btu input rating of all appliances within the space (often water heaters and furnaces are kept in the same area).

It also cannot be less than 100 in2 (0.06 m2).

You need two permanent openings, at least 3” (76 mm) in dimension. These must start 12” (305 mm) from the bottom and top of the enclosure.

When connecting two spaces on different stories (Section G2407.5.3.2), you need at least one permanent opening (through floors or doors), with a completely open area of 2 in2/1,000 Btu/h (4,402 mm2/kW) of the total Btu input of the all appliances within.

Ensuring Sufficient Outdoor Combustion Air

Combustion air can also be supplied to the furnace mechanically from outside. This supply must have a minimum rate of 0.35 CFM/1,000 Btu/h. You need to account for the total Btu, so look at other relevant appliances in the space (Section G2407.9).

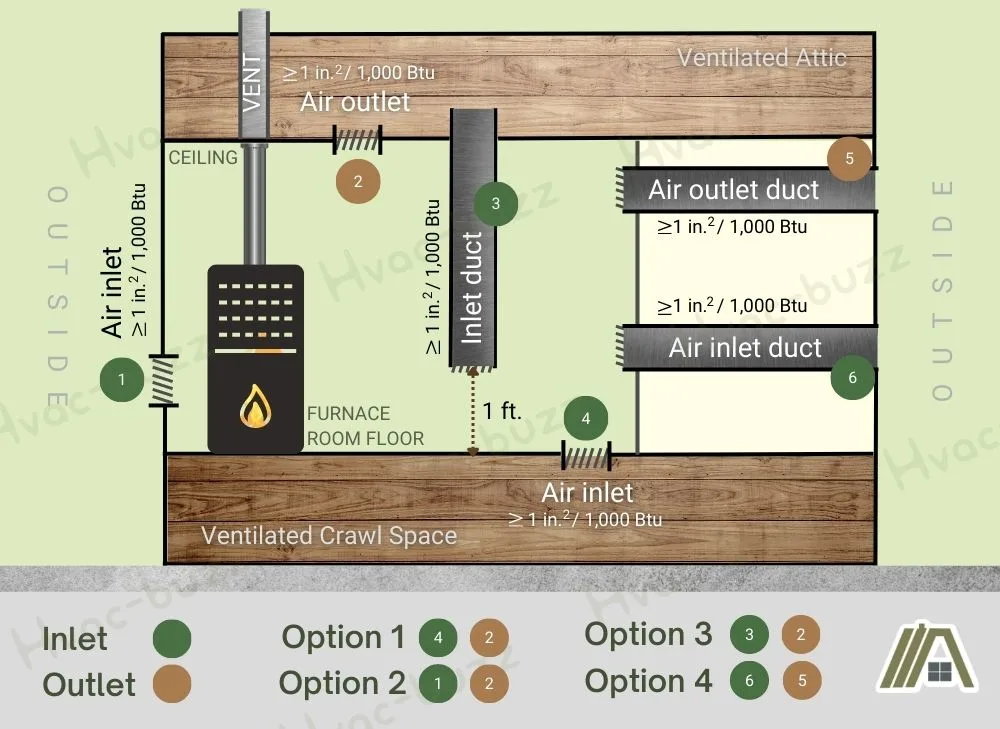

Per Section G2407.6 of the IRC, the openings must be at least 3″ (76 mm) in dimension and can follow one of two methods.

Two-Permanent-Openings Method (Section G2407.6.1)

Like with indoor openings, you must have two permanent openings freely communicating with the outdoors (directly or through ducts). These must start 12” (305 mm) from the top and bottom of the enclosure.

Whether communicating directly or through vertical ducting, the openings must have a free area of at least 1 in2/4,000 Btu/h (55 mm2/kW), and at least 1 in2/2,000 Btu/h (1,100 mm2/kW) for horizontal ducting.

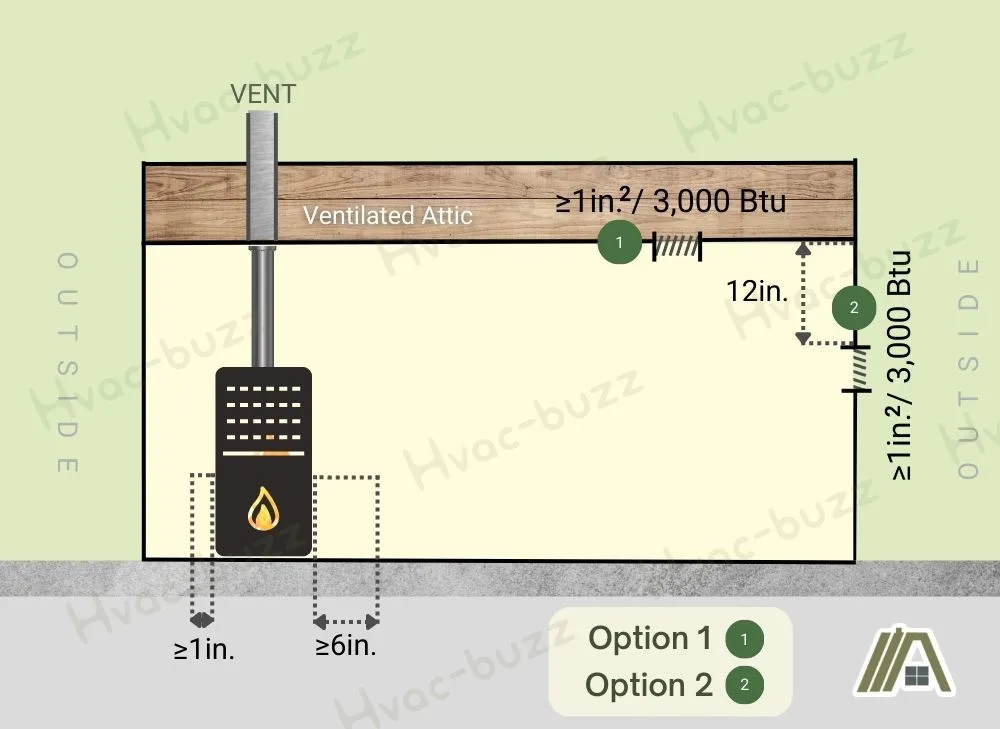

One-Permanent-Opening Method (Section G2407.6.2)

To use one permanent opening, it must start 12” (305 mm) from the top of the enclosure and have free communication directly or through vertical/horizontal ducting to the outdoors.

It must also have a free area of at least 1 in2/3,000 Btu/h (734 mm2/kW), taking into account the total Btu input of all the appliances within the enclosure.

This must also not be less than the combined areas of the vent connectors (which take gaseous by-products to vents) in the enclosure.

Your furnace will need to comply with these clearances:

- Sides and back: at least 1” (25 mm).

- Front: 6” (152 mm).

Ensuring Sufficient Combustion Air (Combo)

Furnace combustion air can also come from a combination of indoor and outdoor supplies (Section G2407.7), and the indoor openings and location for outdoor openings shall comply with the regulations in the previous sections.

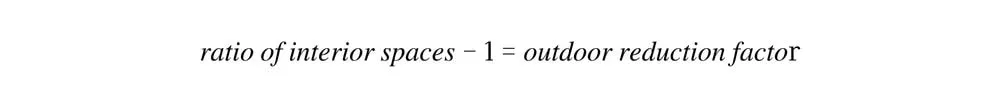

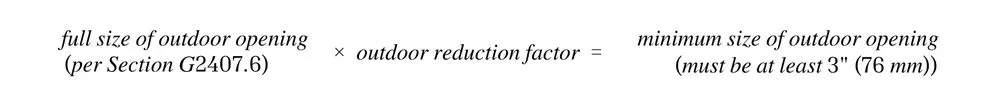

However, calculating the size of outdoor openings is specified by Section G2407.7.3.

Step 1:

Step 2:

Step 3:

Louvers and Grilles

According to Section G2407.10 of the IRC:

- When you know the free area of an opening with a louver, grille, or screen, you can use this to calculate the size of the opening. Where this is unknown, you can assume that louvers have a 25% free area and grilles have a 75%.

- The mesh must be ¼” (6.4 mm) or bigger when using a screen.

- Non-motorized grilles and louvers must be fixed open. Motorized versions must be interlocked with the furnace to ensure they are open before the burner is used (for sufficient air). There must also be fail-safes to keep the burner from starting if they don’t open and to shut off the burner they close during operation.

- Motorized versions must be interlocked with the furnace to ensure they are open before the burner is used (for sufficient air). There must also be fail-safes to keep the burner from starting if they don’t open and to shut off the burner they close during operation.

Combustion Air Ducts

According to Section G2407.11, there are requirements that ducting for combustion air must adhere to in order to ensure it can move air appropriately and can withstand use:

- Must be made of galvanized steel or an equivalent as far as strength, rigidity, and corrosion resistance. Unless you can use unobstructed stud/joist space without removing more than one fireblock.

- Must have an unobstructed termination space (for uninhibited airflow).

- Serve only one enclosure.

- Separate ducts must be used for two opening methods, from the opening to the source of combustion air.

- No screened ducts are permitted if terminating in an attic.

- Horizontal ducts cannot slope downward to the combustion air source.

- The following cannot be used in supplying combustion air: space around a chimney liner, special gas vents, plastic piping within masonry, metal/factory-built chimney. Unless it is a direct-vent gas-fired appliance when the manufacturer allows for installation in a solid fuel-burning fireplace.

- Intake openings on the building exterior must be, at the lowest side, 12″ (305 mm; vertically) or more from the ground level.

Don’t Enclose a Vented Wall Furnace

There is little point in enclosing a vented wall furnace, as it is self-contained (essentially, it has its own enclosure). This furnace is akin to heaters that are mounted on the wall, except it vents combustion by-products through the wall or roof.

An enclosed wall furnace would heat the enclosure, but not the room it is installed in.

Vented Floor Furnaces Are Enclosed

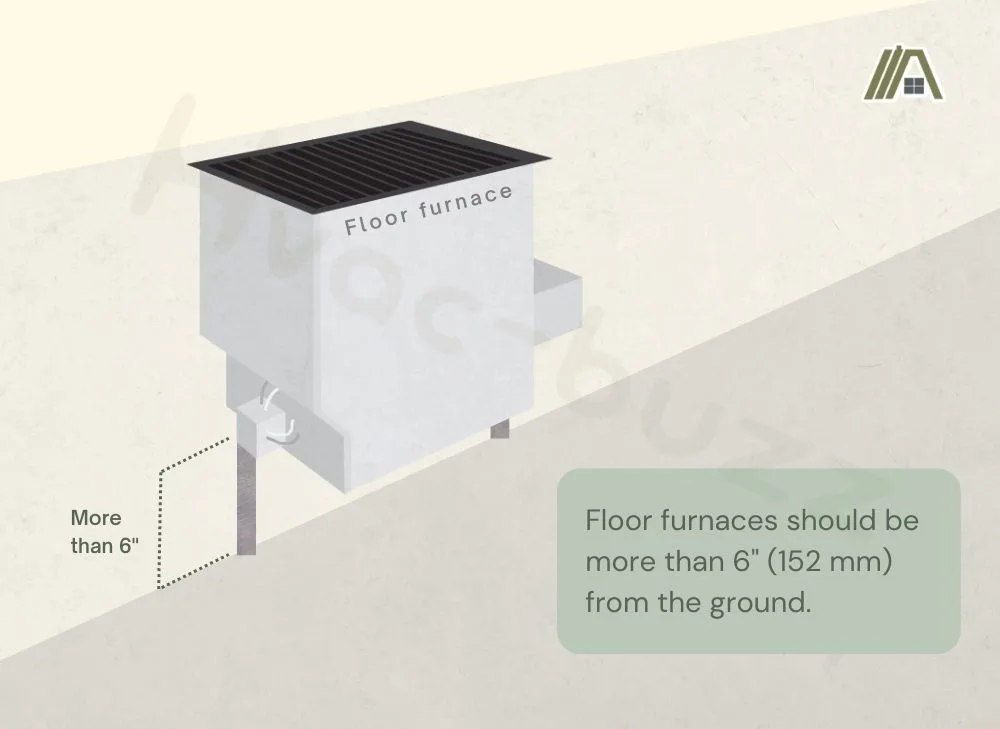

A floor furnace is located in the floor of the house, so it is, by nature, enclosed. Installation of this appliance follows clearances set out by the manufacturer as per Section M1408.2 of the IRC.

However, the building code (Sections M1408.3, M1408.4, and M1408.5) also specifies the following, which influence where under the floor the furnace can be enclosed:

- The furnace can’t extend into an occupied area under the floor (i.e., another room).

- The furnace must be accessible via an opening of 18 x 24” (457 x 610 mm) at minimum or a trap door of 22 x 30” (559 x 762 mm) or larger.

- To prevent water infiltration, a minimum of 6” (152 mm) of space is required between the bottom of the furnace and the ground (not the floor above the furnace).

- If, however, the lower 6” (152 mm) of the furnace are sealed against water, the furnace only needs to be 2” (51 mm) from the ground.

- Furnaces sunk into the ground need a side clearance of 12” (305 mm) from all sides, except the side housing the control panel, which requires 30″ (762 mm) clearance.

Then there are register location requirements that can also influence where in the floor the furnace can be enclosed, according to Section M1408.3:

- Floor furnace floor registers must be at least 6” (152 mm) from a wall.

- Floor furnace wall registers must be at least 6” (152 mm) from the adjoining wall at corners.

- A furnace register must be a minimum of 12” (305 mm) from doors (whether open, closed, or ajar) and combustible items/objects (like curtains).

- Furnace register must be at least 5’ (1524 mm) below projecting flammable materials.

Sources

https://overlandparkheatingandcoolinginc.com/home-furnace/

https://homeguides.sfgate.com/average-btu-furnaces-88602.html

https://homesteady.com/5039424/propane-vs-kerosene-heating

https://www.creia.org/common-venting-of-gas-appliances

https://www.rses.org/assets/rses_journal/0219_Combistion_Air_024_0271.pdf

https://support.sefaira.com/hc/en-us/articles/216886426-Openness-and-Free-Area-Inputs

https://structuretech.com/flexible-vent-connectors/

https://www.familyhandyman.com/article/complete-wall-furnace-guide/

https://betterhomesbc.ca/products/direct-vent-wall-furnace/