Heat pump dryers are energy-efficient, gentle on fabrics, long-lasting, and come with many features. They don’t need a vent, so they can be installed almost anywhere. They are expensive and slow to dry the clothes. If they aren’t connected to a drain hose, the water tank has to be emptied manually.

| Pros | Cons |

| Very energy-efficient. | Expensive. |

| No need to install vents. | Take longer than other dryer models to dry clothes. |

| Dryer can be installed anywhere in the house. | The water container must be manually emptied regularly. |

| Gentler on fabrics than traditional dryers. | Fewer options and limited availability. |

| Can be connected to a drain hose. | Potential for mold growth |

| Long-lasting. | |

| Modern design and features. |

Pros of Heat Pump Dryers

Very Energy-Efficient (Low Run Costs & Eco-Friendly)

Heat pump dryers are the most energy-efficient dryer models out there.

Electricity powers the heat pump of the dryers, but the air is heated by refrigerant enclosed in coils.

When the refrigerant passes through the narrow parts of the coil, the pressure increases and causes the temperature to increase as well. Air passing over these coils is heated.

When the refrigerant passes through the wider parts of the coil, the pressure and temperature decrease. When air from the drum is passed over these coils, it is cooled, water condenses out, and the air is heated again.

Powering a heat pump requires a lot less energy than powering an electric heating element.

Heat pump dryers reduce energy usage by 28%-50% compared to conventional electric units.

Gas dryers also do not use electricity to heat the air. However, comparing the gas energy consumption of gas dryers to the electrical energy consumption of heat pump dryers shows the latter to still be more efficient.

Lower electricity usage equates to monthly savings and also makes an impact on the amount of fossil fuels burned, making heat pump dryers the more eco-friendly option.

There are also secondary energy-saving benefits of heat pump dryers.

As the air from the drum is cooled, dried, and heated again until the program is completed, the dryer does not keep pulling in air from the surrounding environment.

This means that your HVAC system is not constantly having to condition new air as the previously conditioned air is used and expelled by the dryer, which is what happens with traditional electric and gas models.

How Much Money Do Heat Pump Dryers Actually Save? (Load, Year, Lifespan)

Heat Pump Dryers Are Ventless Dryers

As mentioned, heat pump dryers are a type of ventless dryer. This means that they are specifically designed and engineered to function without a vent.

That’s not to say they don’t produce humid, lint-laden air when drying clothes; however, ventless dryers deal with lint and moisture removal in a different manner than traditional, vented dryers.

How Heat Pump Dryers Deal With Lint

We’re all familiar with lint—that fluffy, annoying mass of fibers that sheds off our clothing and collects in our dryers’ lint filter.

When it comes to vented dryers, we know lint is collected on its way out, right at the beginning of the duct used to vent the moist dryer air, and any lint that is not caught is simply removed from the house.

But heat pump dryers collect lint a bit differently since their drying and filtering processes are all completely internal.

The drying process involves a repeated heating and cooling of the air, and we’ll detail this cyclical process more in the next two sections. However, you should know that the air leaving the drum is double filtered to get rid of lint.

Cooling the Air in a Heat Pump Dryer

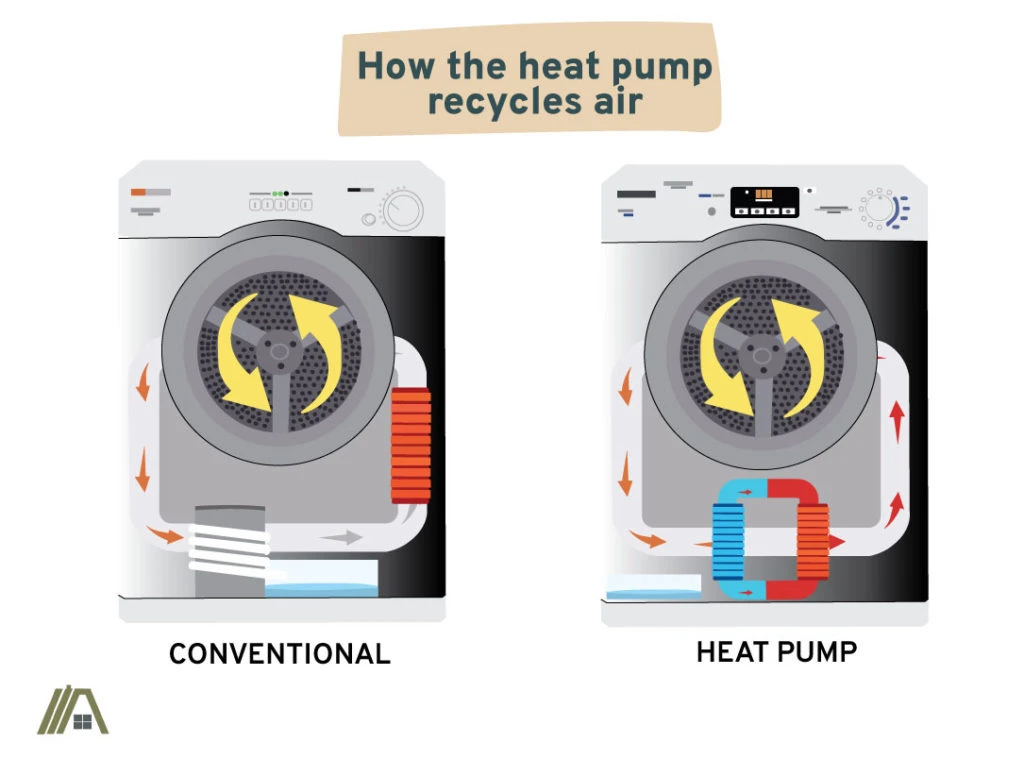

Heat pump dryers are so named because they use heat pump technology in order to dry your laundry, recycling the same air by cooling and reheating it over and over.

It is this cooling of the air that is key to their design, enabling heat pump dryers to clean their air internally without the need for an external vent, and we’ll get into why that is when we explain how heat pump dryers collect water. First, let’s briefly explain the cycle of heating and cooling.

A heat pump dryer will take in air, which it then heats and pushes into the drum. Inside the drum, the hot air removes moisture from your clothing in the form of steam.

Next, this hot, humid air moves out of the drum. It is here that it is filtered for lint, and cooled by passing over coils filled with refrigerant in cold, liquid form.

Lastly, it is reheated by blowing over coils in the compressor, which are filled with hot, gaseous refrigerant. The air moves back into the drum to continue the cycle.

Heat Pump Dryers Condense and Collect Moisture

As mentioned, the cooling step of the heat pump dryer’s process is the reason a heat pump dryer is able to clean its air of moisture internally, without the use of a vent.

As you may know, evaporation is when heat causes water to become gaseous, and condensation is when cooler temperatures enable water to return to a liquid form.

Because hot, steamy air goes through a contained cooling cycle within heat pump dryers, the moisture it contains is able to condense back into liquid. From here, the water may take one of two pathways depending on the dryer’s model and how it is set up.

First, the water may drain into a collection drawer, which must be regularly emptied. Otherwise, if the dryer has been set up to automatically drain the water through a hose, then that is the route it will take.

They Are Convenient

No one will argue that bringing an appliance home, plugging it in, and dusting off your hands after a job well done is much easier than having to run ducts through the innards of the house and cut holes in your walls, ceiling, and roof.

Thus, heat pump dryers lay claim to greater installation and setup convenience than their traditional counterparts.

Additionally, with a vented dryer, you are limited as to where you can install the dryer. Without access to an external wall or the roof, installing a traditional electric or gas dryer is very difficult or even impossible.

This flexibility is great for individuals who do not have a laundry room or people who aren’t sure of the best location for the dryer and would rather not make any permanent changes to their home.

Heat pump dryers come in smaller sizes, so they are also ideal for people who live in tight apartments.

They are also perfect for anyone who cannot or does not want to install a dryer that vents outdoors. For instance, individuals who wish to install their dryer in an enclosed space, like the master closet, or people who live in rentals and aren’t permitted to install a vent.

If you do not have a laundry area, installing a vented dryer can negatively affect the aesthetics of the space. With heat pump units, you wouldn’t have to worry about that.

Relatively Gentle on Clothes

Tumble dryers in general have a reputation for causing fabrics to shrink and wear a lot faster than they should.

However, some dryer models are a lot more dangerous to the health of your clothes than others.

The level of shrinkage is linked to the heat to which the fabrics are exposed. Gas dryers are known to operate at the highest temperatures. But electric dryers have drying temperatures only a few degrees lower.

A heat pump dryer has a much lower operating temperature because the heat generated and imparted by the refrigerant is incapable of reaching the temperatures generated and imparted by electric heating elements and gas-powered flames.

This makes heat pump dryers gentler on your clothing.

Can Be Connected to Drain Hose

The water condensing out of the air exiting the drum has to go somewhere. Typically, this is a water collection tank.

However, most models give you the option of connecting a drain hose to the dryer. This can empty into a convenient sink or it can be plumbed in and linked to your laundry drain.

This allows you to forget about having to manually empty the water container and instead drain water from your appliance through the drain pipe.

Great Durability

The greatest difference between heat pump dryers and other dryers is one that is linked to the durability of the appliances.

The method of heating and the fact that such great temperatures cannot be attained by a heat pump dryer means that the acceleration of wear and tear caused by the heat is lower in these ventless models.

This is clear by the projected lifespans of the different dryers. Heat pump dryers typically have a life span of 20 years, while the life expectancy of traditional dryers is, in general, somewhere between 10 and 13 years.

Modern Design and Features

Heat pumps are a fairly new technology and, in a way, it is more complicated than that of traditional electric and gas dryers.

As a result of this, heat pump dryers typically have modern designs and features.

Most heat pump dryers feature an auto-sensing technology that detects moisture and automatically stops the cycle once the laundry is dry. This way, drying is gentler and more consistent. It also helps you save energy.

One of the main complaints people used to have about heat pump dryers is that they were all compact and had a small load capacity. However, nowadays, there are brands that provide heat pump dryers with the capacity of a regular dryer.

Furthermore, heat pump dryers also feature multiple drying settings to appeal to different fabric types.

Cons of Heat Pump Dryers

High Price

Heat pump dryers cost more than traditional models. They are arguably the most expensive type of dryer out there.

The allure of heat pump dryers is their energy efficiency. However, the savings per cycle will not quickly compensate for the high initial price. This will take time.

Furthermore, it is not a cost-effective option for people who do not do washing regularly or who prefer to air dry their clothes because the amount of money the dryer will save them throughout its life might not be worth their initial investment at all.

Take a Long Time to Dry Clothes

While lower temperatures equate to lower energy consumption and less damage to clothing, they also mean that less moisture is removed from clothing per unit time.

In other words, they take longer than other dryer models to dry a load of laundry.

Vented dryers typically take between 30 and 45 minutes to dry an average laundry load.

It would take a condenser dryer (another type of ventless dryer) between and 60 and 75 minutes to dry the same laundry load.

A heat pump dryer, on the other hand, would require 80 minutes to 100 minutes to dry the same load of laundry.

Additionally, many heat pump dryers are smaller than traditional models (although comparative sized models are becoming more easily available).

A smaller drum capacity means that you have to split your clothes into smaller loads. Therefore, the whole drying process will take up even more time.

The Water Container Must Be Emptied Regularly

Although heat pump dryers come with a drain hose, this feature is only useful if you have a drain area. If the dryer isn’t located close to a basin, sink, or tub, you would be unable to use the drain pipe.

So, if you are unable to link the hose to a drain, you’d have to make do with the water tank. The water container is not automated, and the water inside has to be manually emptied regularly (preferably after one or two loads).

This can get tedious and even messy.

The good news is that there are many uses for this condensed water that could both help you save some money and have a lesser impact on the planet.

Fewer Options and Limited Accessibility

Particularly in the USA, where ventless dryers are a lot less popular than electric and gas dryers, you can encounter difficulty in finding heat pump dryers.

Furthermore, even if you were to find some available to you, the array would likely be limited in terms of size and feature variations.

Potential for Mold Growth

Standing moisture attracts mold, which, once it takes hold, spread quickly and is difficult to get rid of completely.

Vented dryers remove the moisture-laden air from the machine immediately whereas heat pump dryers condense and store the water within the machine.

Even when they are plumbed in, the water is still first condensed inside the machine. A small amount remaining after the rest is drained out is sufficient to support mold growth if there are spores present.

Regularly emptying the tank and assessing it for signs of mold growth is vital.

Sources

https://www.coolblue.nl/en/advice/heat-pump-dryer-or-condenser-dryer.html

https://www.albertlee.biz/blog/Guide-get-pumped-about-heat-pump-dryers

https://www.beko.co.uk/lifestyle/benefits-of-a-tumble-dryer-heat-pump

https://www.energystar.gov/products/heat_pump_dryer

https://www.youtube-nocookie.com/embed/zw183KZQNwc?width=640&height=480&iframe=true