A dryer belt in optimal conditions will last several years. While it will, of course, still wear out over time and potentially even snap, if you replace your dryer belt more than once or maybe twice in its decade-long life, you have a problem on your hands.

There are several potential reasons for repeated belt breakage, but more than knowing what they are, you need to know how to identify your issue from the list and how to fix it.

Dryer belts will break time after time if they are improperly installed, the wrong size for the dryer, or if the dryer is often overloaded. A broken pulley system, damaged drum felt seal, blocked blower wheel, or seized drum rollers would also cause the belt to keep breaking repeatedly.

What Causes the Belt to Break?

If age is not the reason for your snapped belts, then your problem lies with tension and friction.

In other words, some other factor or component is creating too much tension or friction, making your belt wear out and fail much sooner than it should.

7 Reasons Why Dryer Belt Keeps Breaking

1. Improper Installation of the Belt

While every part of your dryer may be perfectly functional, you may still have a problem if the belt is incorrectly installed.

First, ensure that your new belt is placed the correct way up. The side of the belt that is grooved or ridged should be placed inward so that it is in contact with the drum and pulley wheels.

If the belt is installed upside down, the grooves on the motor pulley can burn through the flat side of your belt and tear it into strips.

Secondly, you should make sure your belt is properly aligned. If the belt is placed off-center on the motor or idler pulley, it may not necessarily pull itself into place as the dryer runs.

This would cause your belt to endure sideways tension while the dryer runs in addition to the tension it is meant to handle, causing damage to occur more quickly.

2. Overloading the Dryer

Overloading the dryer is an easy mistake and one that many people make. This may not be a big deal if it only happens every now and again, but repeatedly overloading your dryer will certainly wear down its components.

Overloading can occur if the clothing you put into the dryer is too heavy and wet or if you simply place too many clothes inside at once.

The excess weight of a too-full drum places an inappropriate amount of stress on your dryer’s components. The parts must endure more friction and tension than they were meant to in order to properly operate and turn the drum—and we know what friction does to a belt.

3. Wrong Belt

While most dryers function very similarly on the inside, their part sizes will vary. The dryer belts are no exception to this.

Each dryer model is built to handle a certain amount of weight or to be capable of performing certain tasks. The size, weight, and strength of each piece are chosen and manufactured to balance out with the other parts, creating a system that operates smoothly and efficiently.

Different models may require thicker or thinner belts to handle more or less weight, or they may be longer or shorter to fit over certain drum sizes.

Belts also have varying types or sizes of grooves in order to create more or less friction, or to fit perfectly into the matching grooves on the pulleys’ belt slots.

There are many different reasons one belt differs from the next.

Using an incorrect belt for your dryer model can definitely cause early breakage as it is not designed to work in tandem with the other parts.

So, belts are not interchangeable, and you need to identify the correct size. If you are looking for help finding the right belt for your dryer, I recommend reading through my ultimate guide.

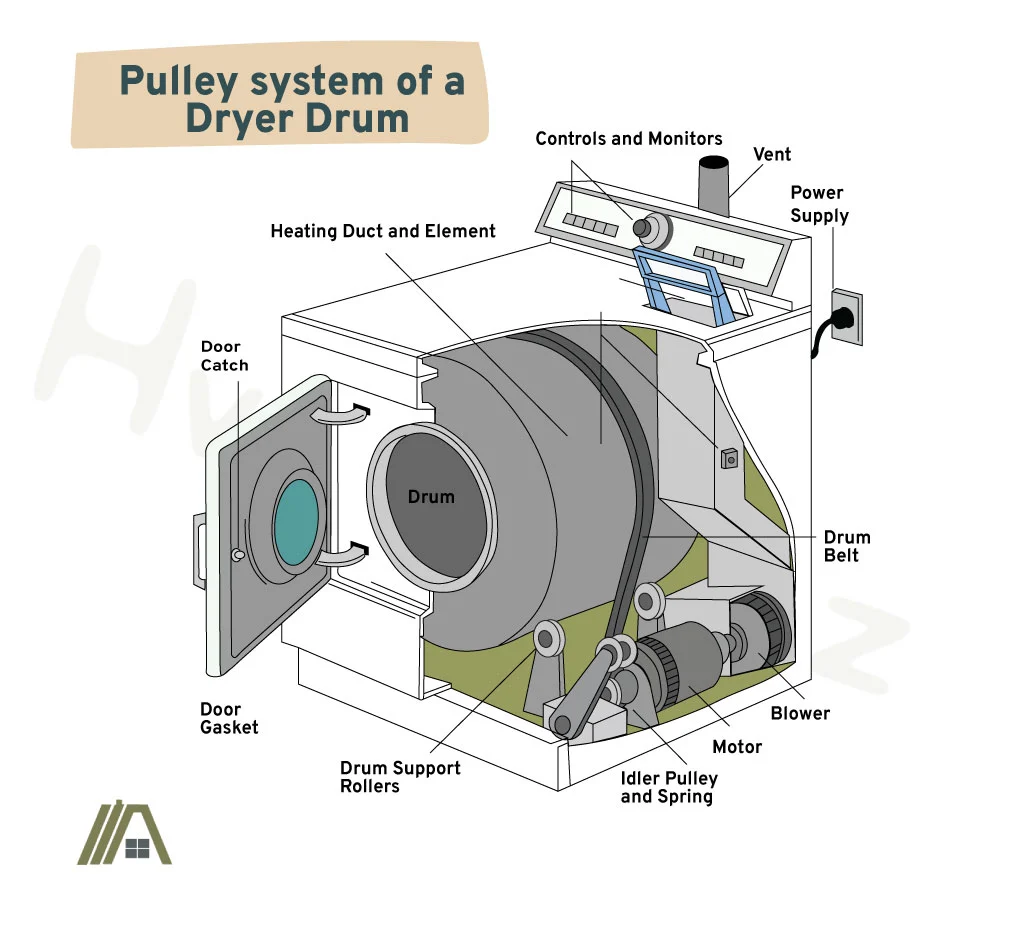

4. Broken Pulley

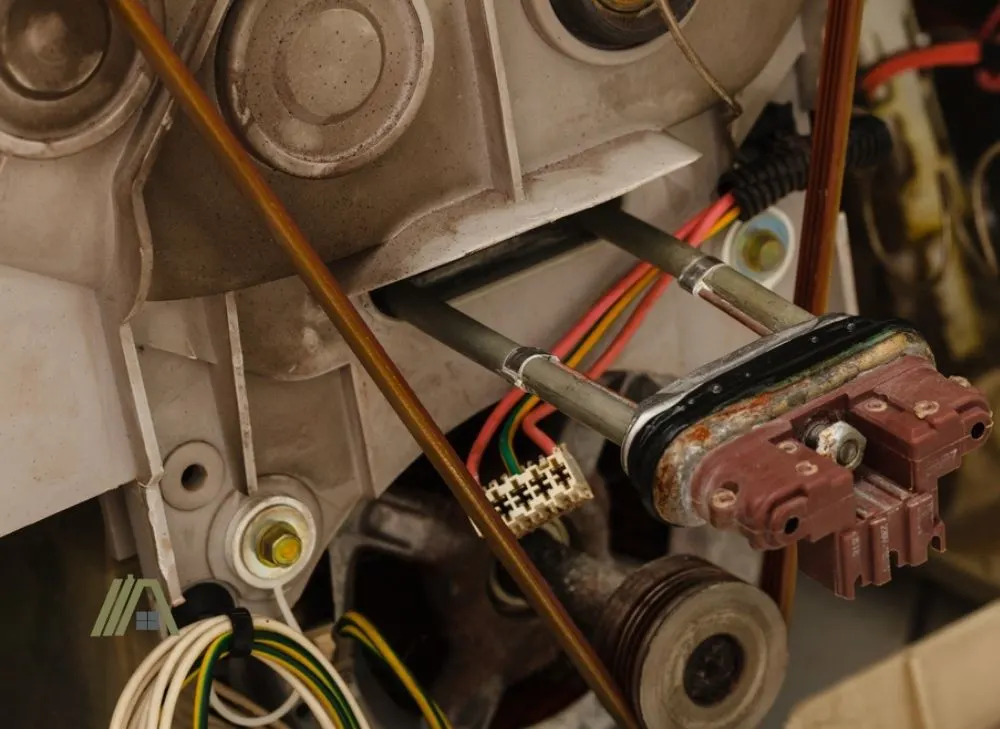

There are a few signs to watch out for that may indicate that the problem lies with your idler pulley or your motor pulley.

If your dryer rotates but makes a squealing sound, or if it rotates but clunks intermittently, you ought to check and see if your idler pulley or motor pulley are the issue.

You will also want to check your pulleys if your drum does not rotate at all or if it spins when it is empty but not when there is a load inside of it.

Your idler pulley may fail to operate if there is a problem with the pulley bearing or the spring.

As for the motor pulley, its grooves may wear down and make it difficult to “grip” onto and pull the belt.

While these are functional problems, it is also possible for lint to build up on your pulley system, drying it out and increasing the level of friction that occurs.

5. Seized Drum Rollers

If you are hearing a thumping noise while your dryer is running, you may want to take a look at your drum rollers to ensure that they are not the problem.

This thumping could indicate a flat spot on one or both of your dum rollers, which can occur if one of them has seized or stopped moving long enough to be worn down.

While a flat spot may seem like a minor problem, the slight jostling and movement that it causes can be enough to stress out and damage your belt much more quickly than a smooth rotation of the drum.

To fix this issue, you’ll not only need to replace the affected rollers but also check for and clean off any hair or lint that has built up around them.

Do not use lubricant on the dryer rollers no matter how tempting it may be. Lubricants and other products, such as WD-40 are flammable and can also cause dirt to gather on the rollers much faster.

Hair buildup is one of the most common causes of a roller seizing up, so checking for buildup can prevent your new rollers from enduring the same damage.

6. Damaged Drum Felt Seal

If you’ve ever taken note of the drum felt seal on the inside of the door, you may not consider it to be a particularly integral part of your dryer’s functioning.

In reality, this felt seal serves two major purposes. The first is to prevent clothing from finding its way into the gap between the drum and the door. The second is to reduce friction.

The placement of the seal keeps the drum from rubbing against the front panel of your dryer. If the felt seal has fallen off or become misplaced, the drum’s rubbing against the door panel may be creating drag.

This drag creates friction, and as we know, excess friction increases wear and damage to your dryer’s components.

7. Blocked Blower Wheel

Last but not least, you will want to check on your blower wheel, especially if you have noticed a high-pitched squealing noise, loud vibrations, or thumping noises while running the dryer.

The blower wheel is meant to circulate the air within your dryer and send it back out through the exhaust vent.

Much like other parts of your dryer, lint can build up on the wheel and prevent it from blowing. It is also capable of snagging small items like socks, hairballs, or dryer sheets.

If your blower wheel collects buildup, it can drag on the motor and create problems with heat and friction. This could not only be the cause of a broken belt, but it may be a fire hazard.

Additionally, if you have been noticing that your clothes take a long time to dry or are coming out too hot, that is another sign that your blower wheel is the problem. This increased heat or extra time running could also be contributing to your belt’s wear and tear.

Average Lifespan of Dryer Belt

On average, a dryer will last about 8 to 14 years. As with any appliance in your house, the more you use your dryer the quicker it will break down from wear and tear.

The belt is a key component to a properly functioning dryer. The belt wraps around the drum of the dryer and is what spins your load of clothes as they’re drying. Again, more loads of clothes will shorten the lifespan of your belt and dryer.

If your dryer is getting older, it becomes more and more likely that the belt will break. Thumping sounds during operation are a good indication of the belt stretching from tight to loose.

Similarly, a broken belt could also produce thumping noises. However, it may seem as though the rest of your dryer is functioning fine as the dryer boots up normally. You can be sure that the belt is the problem if the drum is not spinning or stops premature to the end of the cycle.

Sources

https://ars.repair/dryer-repair/checking-the-blower-wheel-for-lint-clogs-in-your-dryer/

https://bcalease.com/faq/troubleshooting-your-equipment-dryer/

https://www.doityourself.com/stry/4-signs-that-you-need-a-new-dryer-blower-wheel

https://homeguides.sfgate.com/dryers-pulley-broken-41150.html

https://homeguides.sfgate.com/how-to-know-when-to-replace-a-dryer-filter-13768639.html

https://homesteady.com/info-12123535-purpose-felt-seal-dryer.html