The best materials for insulating a home should provide the highest performance. Two popular options are cellulose and fiberglass insulation, each with unique benefits but both with definite drawbacks. It would be helpful if mixing them means they cover each others’ weaknesses.

Mixing insulation types is not uncommon, but the method of mixing makes a difference.

There are issues with mixing cellulose and fiberglass together. Layering new fiberglass or cellulose over old cellulose or fiberglass is a common practice but it can cause accelerated or uneven settling and uneven R-values. Mixing the two materials before installation is not worth the trouble and mess.

Mixing Method 1

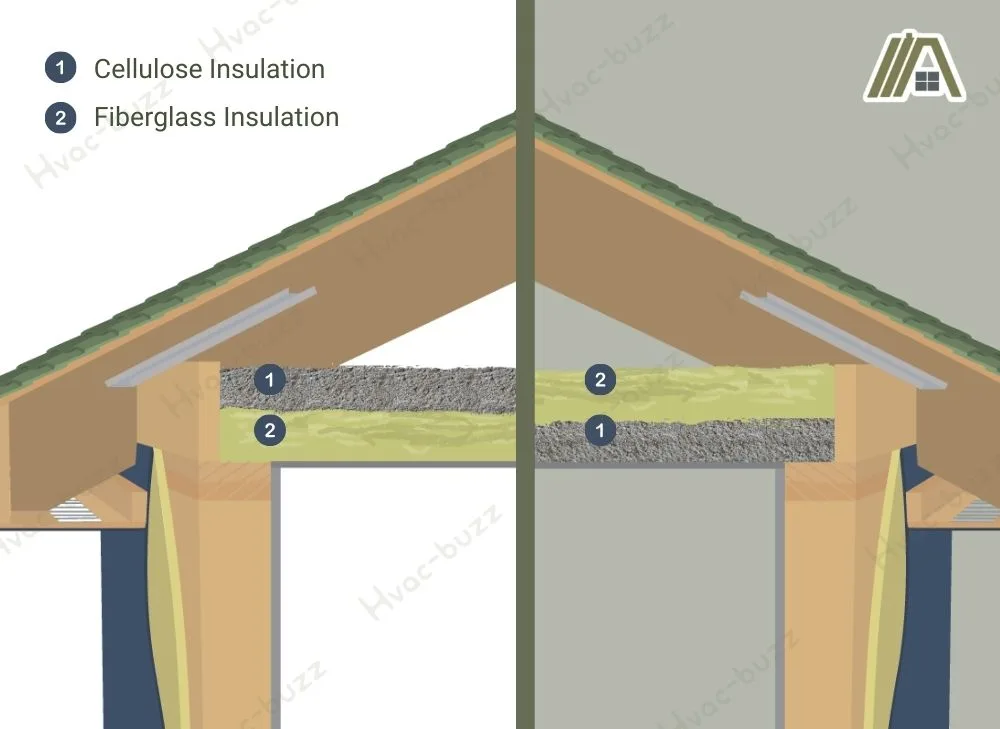

The first way that fiberglass and cellulose insulation are mixed is when one already exists and the other is installed over it.

This could be old fiberglass batts or loose-fill, and you cover it with new cellulose. Or perhaps the cellulose was laid first and now you want to boost the lost R-value by blowing fiberglass over the cellulose.

Not only is this allowed but it is actually a really common practice. You don’t have to update your insulation with whatever type was first installed.

The freedom to choose fiberglass over cellulose or vice versa means that you can control the additional benefits. I say additional benefits because you have to install enough of either to achieve the minimum required R-value, so it comes down to the bonus features.

Advantages

If you currently have fiberglass insulation, you can install cellulose over it in order to benefit from the greater ability of cellulose to block out sounds.

This can bring peace of mind that your neighbors won’t be able to hear you and it can also block out the noise of traffic, nearby construction, barking dogs, etc.

Mixing the two insulation types is going to be a lot cheaper and time saving than if you were to remove the old insulation to replace it with the new one of your choice.

Typically, fiberglass is slightly cheaper than cellulose insulation, which means that if you already have cellulose, you can top up your insulation with a cheaper option. In addition, if you have fiberglass but you come across a really good deal for cellulose, you can take advantage of this special price.

Cellulose is more vulnerable to water, so if your insulation gets wet, you might be able to separate the majority of the material in the layers and dry out the fiberglass, saving a good chunk of your insulation and lowering the cost of replacement.

Issues

Cellulose is denser than fiberglass, which means that per inch, it is going to be heavier.

When you install cellulose over fiberglass, there is a risk of accelerated settling, which means that you will have top up your insulation again sooner. However, it is more likely to be a difference of a year or two as opposed to halving the life of the insulation.

Blowing one type of insulation over another type of blown insulation can lead to uneven settling if more cellulose ends up over one part of the fiberglass than others.

This way of adding insulation also means less control over the final R-value. Cellulose has a slightly higher inherent R-value, so if one part has a greater ratio of fiberglass to cellulose, you end up with a lower R-value in that area. This can happen even when you install the correct amount of insulation.

You cannot install new insulation over old insulation if there is a problem with the old insulation, like mold.

Mixing Method 2

The second way that cellulose and fiberglass can be mixed is to mix bags of cellulose with bags of fiberglass before installation.

I have not heard of anyone using this method. This is because, while there are advantages, there are more issues.

Advantages

As with the previous method, by mixing the bags together, you can cut your costs a bit but still get good insulation and some bonus soundproofing.

Unlike the first method, however, you can ensure a much more even coverage by mixing the materials together at the start.

In addition, the issue of accelerated settling is much lower because the cellulose is not layered on top of the fiberglass. Instead, it is spread evenly throughout the full thickness of the insulation. This is not to say that the settling won’t happen quicker, it just means that it is slower and/or less likely.

Issues

Mixing cellulose and fiberglass before installation is going to be a tedious and messy task, particularly if you are trying to get a proper ratio and distribution.

Furthermore, you increase your exposure to the insulation materials. While they may not be terribly dangerous, they are also not completely harmless.

Because cellulose is more vulnerable to moisture, if your insulation gets wet, you cannot isolate the beyond-help cellulose from the can-be-saved fiberglass. You have to toss the lot or risk mold growth.

Sources

https://www.energy.gov/energysaver/types-insulation

https://www.epa.gov/mold/brief-guide-mold-moisture-and-your-home

https://www.pnnl.gov/main/publications/external/technical_reports/PNNL-20972.pdf