The overhead position of ceiling fans means that they are often forgotten during routine appliance maintenance or cleaning. If not forgotten, then the fact that you often need a ladder to work on them, means that ceiling fan maintenance is the task we push to tomorrow, next week, next month, etc.

However, if you do not maintain your ceiling fan properly, you are not just going to scatter clouds of dust whenever you turn it on. Ceiling fans need regular maintenance to ensure that they run smoother for longer and last as long as possible. Let’s look at why and what maintenance is required.

Ceiling fans require regular maintenance to remain in good running order. Maintenance should include regular cleaning, checking for any wobbly movement, and tightening loose screws. Keeping the ceiling fan blades balanced will keep it running smoothly. Older ceiling fan models may need oiling.

Good Maintenance Improves Performance and Lifespan

A ceiling fan’s function depends on movement, so any minor issue can quickly escalate if it goes unattended. A loose screw in the junction box may cause a slight wobble that could become a catastrophe over time.

The optimal functioning of ceiling fans depends a lot on the condition of the motor and balance. These two factors are inextricably tied together.

- A wobbly, unbalanced fan will not only be annoying but also places additional strain on the motor to keep the blades rotating.

- A faulty motor may create jerky movement, which will likely result in the blades becoming unbalanced.

Keeping the fan clean and balanced through regular checks and light maintenance will keep it running smoothly for up to a decade and eliminate annoying sounds (at both low and high speeds). That’s a long time for most appliances, so it’s well worth the effort.

Ceiling Fans Need to Be Kept Clean

Ceiling fan blades are large, flat surfaces that are effective dust collectors. The top of each blade is well out of view, so it can be easy to forget that grime may be quietly building up, particularly in the kitchen. The problem with dust and grime accumulation is that it can be more serious than you think for ceiling fans.

Astoundingly dust build-up is one of the top causes of ceiling fan wobble. The blades of fans are designed to spin at precisely the same level. If there is a weighted dip in one blade, the fan will spin unevenly. It might not be immediately noticeable, but over time the added weight on the blades adds strain to the motor.

A build-up of powdery dust on the top surface of the ceiling fan can also become a health hazard if you have allergies. Each time you hit the switch to enjoy some cooling action, dust particles are being kicked up into the air and showered around the room.

Cleaning the Blades

Ceiling fan blades should be routinely dusted at least once each week. Fortunately, this doesn’t mean that you will have to scale a ladder every time, as there are specially designed dusters that allow you to effortlessly reach the upper surface of your fan’s blades without stepping off the ground.

To routinely dust fan blades, you will need a specialized fan cleaning tool that allows you to reach up and clean both sides of each fan blade simultaneously.

An excellent choice for this task is the Ettore 48211 Ceiling Fan Brush (amazon link) that slides over each fan blade. The split tips of the fibers attract dust particles, so all you need to do is slide each blade between the brush, and voila, your fan will be clean, top and bottom.

If you don’t have a long pole, you may also need the Ettore 45700 All Purpose Interlock Pole (amazon link) that will allow you to reach even the highest ceiling fans in your house.

For a deeper clean, especially if you have forgotten to clean your fan blades for a while, it may be necessary to use a sturdy ladder and wipe the top of each blade with a damp microfiber cloth. Don’t press too hard and use your hand to provide counter pressure on the other side of the blade.

Once you are safely down from the ladder, switch the fan on to dry the blades immediately so dust doesn’t get stuck on the damp surface.

Never use any harsh or abrasive chemicals to clean your ceiling fan blades. They may tarnish or discolor the blades. Also, avoid anything that may leave a glossy residue that dust could stick to when you’re finished cleaning.

Cleaning the Motor

Liquid cleaners and fan motors should never meet. A fan’s motor is an incredibly fine-tuned mechanism that must stay completely dry. So, put away your cleaning sprays and damp cloths when you need to wipe down your ceiling fan’s motor.

If you are simply doing routine maintenance and checks, it is best to remove dust from the outside of the fan’s housing using a soft dry cloth. The Fanbladecleaner fan duster (amazon link) can be used to clean all outer parts of your ceiling fans.

To clean the inside of a fan motor, a handheld compressed air duster like the one from ATEngues Store (amazon link) is ideal for blowing dust out of the unit.

Loose Screws Should Be Tightened

Every so often, it is important to turn off the power to the fan at the breaker box so that you can safely perform a thorough inspection of every aspect of the appliance. Screws are present in all parts of most ceiling fans.

- They attach the junction box inside the roof to the support stud.

- They attach the fan to the junction box.

- They keep the motor canopy closed.

- They are used to attach the blades firmly in place on the flywheel of the fan.

- They are used in the light fixtures.

Movement from the rotation of the blades can result in some screws working themselves loose, which affects the functionality of the entire unit. One sign of loose screws is noise. If your fan is making clicking or grinding noises, then tightening up the screws is a good first step to regaining your quiet fan.

Routinely check that all the screws in each part of the system are still holding securely. Also, ensure that the screws holding the junction box to the stud are tight. Wood can weaken over time, which may affect how tightly your fan is connected to the beam in the ceiling.

Examining the Fan

Before you switch off the fan at the breaker box to work on it, take some time to study its movement. Is it running flawlessly, or are there any weird sounds, grating, straining, or a wonky spin as the blades rotate?

Next, make sure that the power to that unit has been switched off at the breaker box and grab a sturdy ladder. While on the ladder, check that the blades are all uniform and hanging at the same level. Now, go over each section of the fan with a screwdriver, checking that all the screws and fittings feel tight.

Use a yardstick to measure each blade from the same point to the roof. It is often possible to gently mold the offending edge back to the same angle as the others.

It may be necessary to take a trip into the attic or ceiling to confirm that the junction box is still securely attached. Also, check that the screws holding on the light fixture are adequately tightened.

Ceiling Fans Should Always Be Balanced

Fan blade wobble caused by imbalance is easy to remedy and fix. Telltale wobbling movement caused by a dipping blade or uneven distribution of weight on the blades will quickly alert you that the blades need to be balanced.

Keeping ceiling fan blades balanced is essential because any unevenness will put unnecessary strain on the motor, invariably shortening its lifespan. This is a common issue, and specific inexpensive ceiling fan balancing kits are available (amazon link) that will quickly sort out the problem.

The best way to check that your ceiling fan blades are all running evenly is to use a yardstick and measure the distance from the ceiling to various points on each blade.

Balancing kits contain tiny self-adhesive weighted discs that can be applied to the top surface of fan blades. Follow the directions on the kit to perfectly balance your fan.

Switching Blade Direction Is Important

Ceiling fans do not change the temperature in a room. Therefore, running a fan inside an empty room is not useful unless it is to aid general ventilation or to keep flies off food.

However, the action of the blades can help distribute air currents around the room and switching between the two modes of a ceiling fan can be considered part of routine maintenance.

In summer, the blades of a ceiling fan should be set to move anti-clockwise. The top edge of the blades collects air and pushes it down, creating a wind-chill effect for any occupants in the room.

In winter mode, the direction is reversed, so the air inside the room gets mixed without creating an artificial cooling breeze.

A ceiling fan on its own set in winter mode is not really helpful to warm a room.

When a ceiling fan is set on winter mode and used in conjunction with a heating device like a radiator or space heater, it is a great way to move the warm air around the room. That way, all the occupants of a room stay warmer, and not only if you are sitting near the heater.

Be careful when cleaning the fan that you don’t accidentally flip the switch. There are legitimate reasons for why a fan reverses direction by itself, but unknowingly changing the direction is also on the list!

Do Ceiling Fans Need to Be Oiled

Modern ceiling fans are manufactured with double-sealed ball bearings, so they don’t usually need oiling. They are designed to be self-lubricating and require very maintenance.

Older fans may require routine oil checks, and it is essential to know if yours does to prevent burnout and keep the unit in good running order.

The best way to know if your ceiling fan requires regular oil top-ups is to consult the owner’s manual for the specific model. Most information is also available on the company websites if you can’t locate the manual.

It is important to know if your ceiling fan requires a regular top-up with oil and, if it does, to know what type of lubrication agent it requires.

Most ceiling fans that require regular oil top-ups have a tiny oil hole on the top mounting closest to the ceiling, above the motor. If you don’t see one, your fan probably does not require oiling; however, you should still check with the manufacturer just to be sure.

Oil the Ceiling Fan

If you have confirmed with the ceiling fan manufacturer that it is a model that requires regular top-ups, be sure to add the task to your list of household maintenance chores. There are specific ceiling fan oils (amazon link) available, and they always come in tiny easy to dispense containers.

Never use 3-in-1 oil, penetrating oils like WD-40, or “whatever you have available”, as it may damage the motor.

Ceiling fans will only require a few drops to top up and it is a quick procedure. You shouldn’t even have to take the fan down.

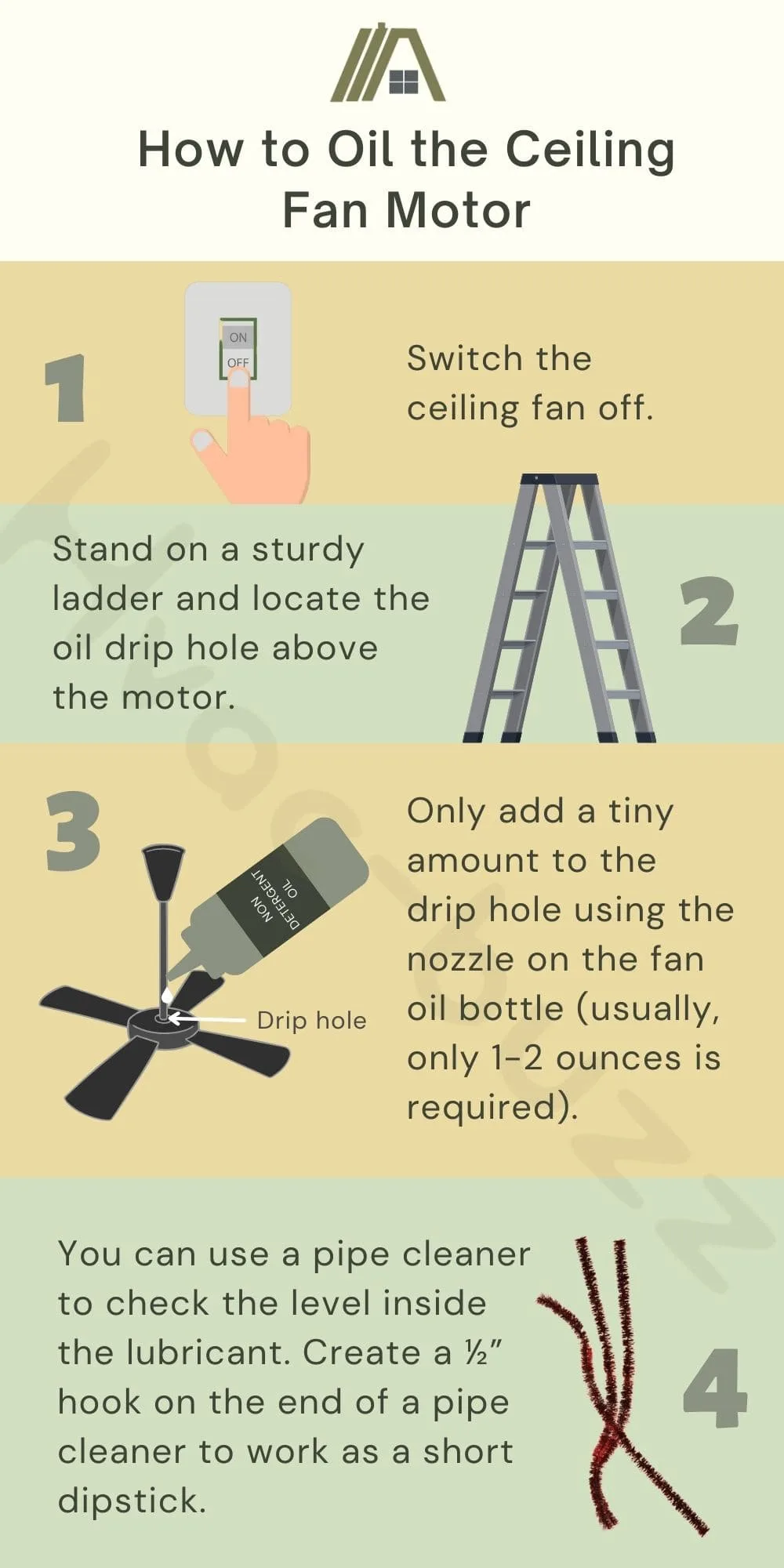

- Switch the ceiling fan off.

- Stand on a sturdy ladder and locate the oil drip hole above the motor.

- Only add a tiny amount to the drip hole using the nozzle on the fan oil bottle (usually, only 1-2 ounces is required).

- You can use a pipe cleaner to check the level inside the lubricant. Create a ½” hook on the end of a pipe cleaner to work as a short dipstick.

If your fan is a model that requires regular oil top-ups, always work in small quantities. Never squeeze large amounts of oil into the fan’s drip pipe. It is unnecessary and could overflow onto the blades, causing a terrible mess around the room when the fan is switched on, not to mention attracting dust and grime.

Looking After the Lights

Many ceiling fans also come with lights. This means that part of ceiling fan maintenance is ensuring the lights are working well and the covers are kept clean.

One relatively common problem with ceiling fan lights is that they don’t come on even though the fan is working. If this happens, then it’s time to do a bit of troubleshooting and implement more maintenance procedures to either prevent this from happening again, or to deal with it more effectively in the future.

Sources

https://www.bobvila.com/articles/cleaning-ceiling-fans/

https://homeguides.sfgate.com/lubricate-ceiling-fans-21316.html

https://www.wikihow.com/Oil-a-Ceiling-Fan

https://en.wikipedia.org/wiki/Ceiling_fan