Waterproofing membranes are typically plastic or latex, come as pre-formed sheets or in liquid form, and are commonly used over surfaces in construction to prevent water damage or leaks. Silicone is also used in construction for protective coatings or as adhesives and also has waterproof properties.

Unfortunately, they aren’t always compatible with silicone, another form of construction sealant. Here we’ll see what makes silicone and waterproofing membranes unlikely to work together. But we’ll also look at some anecdotal evidence that suggests it may be possible. You can even test it yourself.

Waterproofing and silicone are both non-porous substances, which makes adhesion between the two difficult and even impossible to achieve. Most waterproofing materials come with the information that silicone will not adhere to the surface, or that waterproofing cannot be applied over silicone.

Silicone and Waterproofing Both Non-Porous

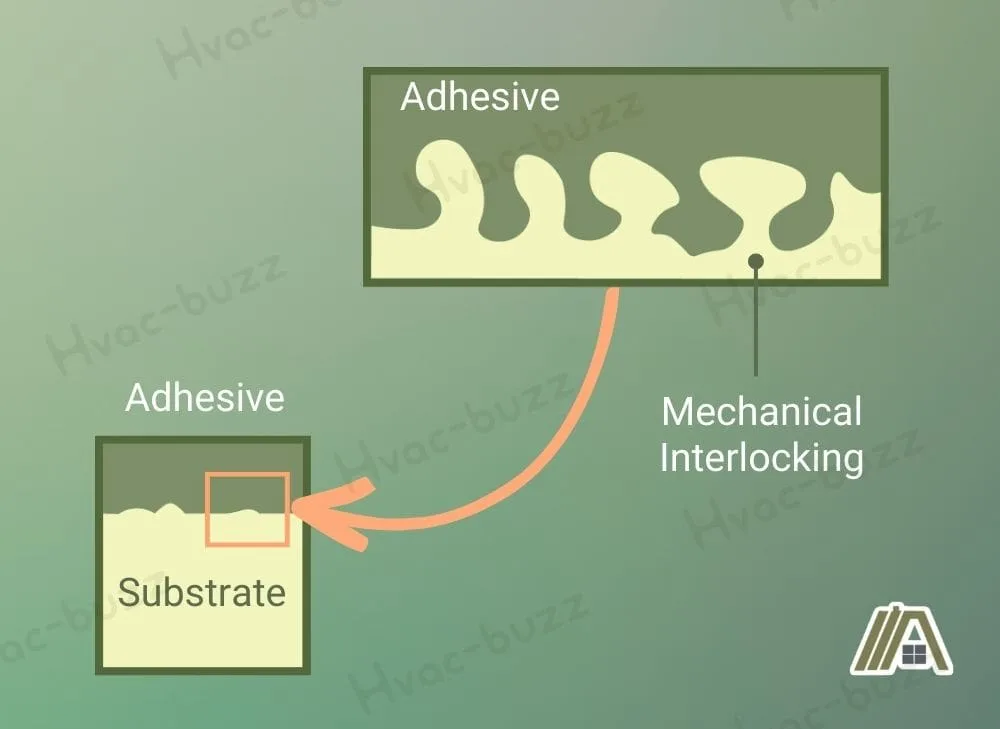

There are different types of adhesion: chemical, molecular, and mechanical. Because silicone and non-porous membrane do not react chemically or by charged molecules, we’ll look at their potential to have mechanical bonds.

Mechanical adhesion occurs when an adhesive fills the pores of a material. The hardening of the adhesive anchors the two substances together (Geminger et al., 2016). For this to work, the adhesion must be between a porous and non-porous material.

Silicone and waterproofing membrane are usually incompatible because both are non-porous. Silicone is often waterproof or water-resistant itself because of this lack of pores. The non-porous aspect of both materials is important to their function but makes the adhesion between them difficult.

Adhesion refers to clinging between dissimilar surfaces, while cohesion refers to similar or identical substances sticking together. While silicone and waterproofing membranes are both non-porous, their molecules aren’t similar enough to produce cohesive forces.

Polyethylene or Polypropylene Sheet Membrane

The solid form of waterproofing membrane—sheet membrane—is commonly made of plastics such as polyethylene or polypropylene. Both these plastics are non-polar, while water is polar, which is what helps (along with their non-porous structure) to protect the surfaces around the membrane from water.

Many silicone sealants state that they don’t stick to plastics:

| Silicone Sealant | Direction on use with Plastics |

| Gorilla Sealant Caulk and Seal Silicone Sealant | “Gorilla Sealant may not work well on certain difficult to bond plastics, such as polyethylene (PE) and polypropylene (PP), or certain types of rubber with high oil or plasticizer content.” |

| Alcolin Silicone Sealant | “Will not adhere to some plastics such as polyethylene, polypropylene and Teflon.” |

| Dap Silicone Max Premium All Purpose 100% Silicone Sealant | “Best adhesion and compatibility are not achieved with substrates made of methylmethacrylate, polycarbonate, polypropylene, polyethylene or polytetrafluoroethylene.” |

As seen, although not completely forbidden, most companies don’t recommend using silicone sealant with polyethylene and polypropylene.

Latex-Based Liquid Waterproofing Membrane

Liquid waterproofing membranes, such as RedGard and Drylok, are latex-based. As with the sheet membrane, this means they are incompatible with silicone because latex is non-porous. There is no opportunity for mechanical adhesion because latex is too smooth.

Similarly, other liquid waterproofing membranes made of “liquid rubber” or vinyl (such as Flex Seal or Duradek products) won’t be compatible with silicone because they are also non-porous.

What do manufacturers say about compatibility?

As already seen, Gorilla Silicone Sealant recommends against its application on some rubbers (latex is a rubber).

RedGard and Drylok Technical Data Sheets don’t discuss interaction with silicone sealants, except to suggest using it at drains where the upper flange and membrane connect.

If you’re not sure whether a sheet membrane or liquid membrane is best for your project, check out this video:

“Case Study”: Silicone Adheres to Drylok

There may be cases when waterproofing membranes and silicone are able to achieve adhesion. For example, in this forum, one user claimed that silicone was able to stick on a Drylok-ed surface in their frog tank.

However, this is only one case, and there is no follow-up information regarding how long the adhesion lasted. Additionally, this doesn’t tell us whether such adhesion would be achieved on a larger scale, as here it was silicone attaching rocks to a Drylock-ed rock structure.

Test for Using Silicone Over Waterproofing

Although most products advise against it, there is some indication that compatibility is possible. For example, Dap’s Silicone Sealant Technical Data Sheet says, “Evaluate such substrates before using sealant” in reference to compatibility with plastics.

Therefore, if you’d like to see if it can work for your project, perform a test first. We’ll lay out a possible method here.

What You Will Need

You’ll first need to choose if you’re using a liquid or sheet waterproofing membrane (use the video above if needed). If you already have your materials purchased, do the test with what you have before purchasing other options. Otherwise, here are some items to purchase.

If available, a small or sample-size option has been provided so that you can test multiple combinations of silicones and waterproofing membranes.

| Item | Purchase Link |

| Henkel Loctite Silicone Waterproof Sealant (2.7 oz ) | View (amazon link) |

| Permatex Black Silicone Adhesive Sealant (3 oz) | View (amazon link) |

| Gorilla Waterproof Caulk & Seal 100% Silicone Sealant (2.8oz) | View (amazon link) |

| USG DUROCK Liquid Waterproofing Membrane (1 Gal) | View (amazon link) |

| Gorilla Waterproof Patch & Seal Liquid (16 oz) | View (amazon link) |

| ATack Fiberglass Waterproofing Sheet Membrane (6” x 75’) | View (amazon link) |

| Schluter Systems Waterproofing Polypropylene Membrane 1/4″ 8.4 Square Feet Sheet (2 Pcs) | View (amazon link) |

| Waterproofing Polyethylene Fabric (8mils x 108 Square Feet) | View (amazon link) |

Step 1: Choose the Test Application Location

Throughout the test, you’ll want to simulate the environment the end combination will experience. Choose a small area in the location where you’ll be combining the silicone and waterproofing membrane or use a sample of a similar base material (e.g., shower or flooring).

If trying out several products, make sure you use similar amounts and a similar test location for the most reliable comparison.

Normally, you’ll first apply the waterproofing membrane and then add the silicone.

Step 2: Apply Waterproofing Membrane

If using a liquid waterproofing membrane, follow the instructions on the packaging. Normally, you apply two coats. Different products will suggest waiting times between coats. The average wait time between coats is 2 hours.

If using waterproofing sheet membrane, again follow the instructions from the company. For a spot test, you’ll cut a square of the sheet and adhere it to the test surface (such as backerboard). Sheet membrane drying times range from 16 hours to 7 days.

Step 3: Add Silicone

Once you’re sure the waterproofing membrane has dried, you can now apply the silicone sealant.

Again, you’ll want to simulate the intended use of the combination, so apply the silicone as an adhesive or sealant in the location you need (connecting the membrane to something else, on top of the membrane, etc.). Allow the silicone to dry.

Step 4: Applying Stressors

Evaluate in your test what stressors may occur in the real-life application. This could include gravity, water, pressure, etc. During and after applying the simulated stressors, check if the materials stay together and still effectively provide waterproofing.

- For gravity (such as in a wall/shower application): you can simulate long-term gravity forces over a shorter period by adding weight to the silicone and waterproofing membrane adhesion. This may involve adhering an object to the testing site.

- For water: Wet the testing site with different amounts and duration of water exposure throughout your trial.

- For pressure (such as in a flooring application): add extra weight to the test by placing a heavy object on the silicone and waterproofing membrane combination. You can try using different weights you think it will experience in real-life applications, like human body weight or furniture weight.

Step 5: Test over Time

Adhesion testing should take place over a minimum of 48 hours, but if possible, should last as long as 7 days (or more if you don’t have project time constraints).

The longer the better. You’re trying to test if the adhesion is sustainable and worth doing on a larger scale. Expect the testing to take a while as both waterproofing membranes and silicones need time to dry.

Step 6: Final evaluation

If the adhesion or waterproofing failed during your test, you can try a new combination of substances or conclude that the silicone and waterproofing membrane aren’t compatible and won’t work for your application. A possible solution is finding a compatible sealant or adhesive to replace silicone.

If the adhesion and waterproofing held up during your test, you can conclude that using the combination on a larger scale may work. Keep in mind though, that you should keep an eye out for failed adhesion or waterproofing because, in theory, silicones and waterproofing membranes are still incompatible.

Sources

https://www.constrofacilitator.com/waterproofing-membranes-types-and-applications/

https://www.sciencedirect.com/topics/engineering/mechanical-adhesion

https://www.alcolin.com/diy-products/sealants/silicone-sealant

https://www.gorillatough.com/product/clear-sealant/

https://www.dap.com/media/3337/dap-silicone-max-all-purpose-silicone_tds_3-3-19.pdf

https://www.sinomaco.com/composite-waterproofing-membrane.html

https://www.custombuildingproducts.com/TDS/TDS-104.pdf

https://www.defelsko.com/resources/test-methods-for-coating-adhesion