As important and helpful as the building codes are, they can sometimes be somewhat confusing or difficult to understand. However, that doesn’t exempt us from following them.

In this article, I go through all the different dryer vent code requirements and explain what they mean and why they are so important.

Manufacturers determine dryer venting. If unspecified, codes apply. Dryers need independent venting systems, terminating outside, away from house openings. Ducts must be smooth, 0.0157" thick, 4" in diameter, and sufficiently long. Booster fans and vent screens are prohibited. Backdraft dampers are mandatory.

Where to Find the Dryer Vent Code

The International Residential Code (IRC) has a whole section dedicated to the clothes dryer exhausts (Section M1502). It covers everything from what size and material the ducting should be to whether or not it is allowed to use booster fans. It even covers ductless dryers.

The IRC applies in all of the states of the United States with the exception of Wisconsin. On top of these 49 states, the code also applies in the District of Columbia, Guam, Puerto Rico, and the U.S. Virgin Islands.

Ductless Dryers Are Legal

Ductless dryers, better known as ventless dryers, use hot air to dry clothes just as vented models do. The difference is that ventless dryers, such as condensers or heat pump dryers, can cool this air and collect the condensed moisture in a water collection tank rather than exhaust it outside.

If you have one of these dryers, then you don’t need to worry about the code. These dryers are still safe even though they do not have any vents. As long as your ventless dryer is labeled and listed according to the IRC, it is code compliant (Section M1502.2).

Manufacturer Instructions Take Precedence

Since different dryers are designed differently, their installation and operation requirements can vary.

The primary purpose of the IRC is to set rules that help ensure people’s safety. However, the code could not possibly cover all the specific requirements for each and every dryer. Nor could it keep up with every minor advancement in technology.

At the same time, the manufacturers know their appliances better than anyone. They can provide the most reliable installation instructions to ensure safety and prevent any potential problems with the dryer, and naturally, it is in their interest to do so.

That is why the IRC Section M1502.1 states that:

“Clothes dryers shall be exhausted in accordance with the manufacturer’s instructions.”

This means that if the manufacturer prohibits venting the dryer through a soffit, venting this specific dryer through a soffit would be against the code, even though the IRC itself doesn’t explicitly prohibit this practice. However, if the manufacturer allows venting through a soffit, then doing so is code compliant.

It is also important to note that if the manufacturer doesn’t clarify certain installation requirements, such as what duct material should and shouldn’t be used, the owner should automatically follow the IRC’s more generalized guidelines.

Gas Dryer | Do You Need a Plumber for the Install? (Code rqmts)

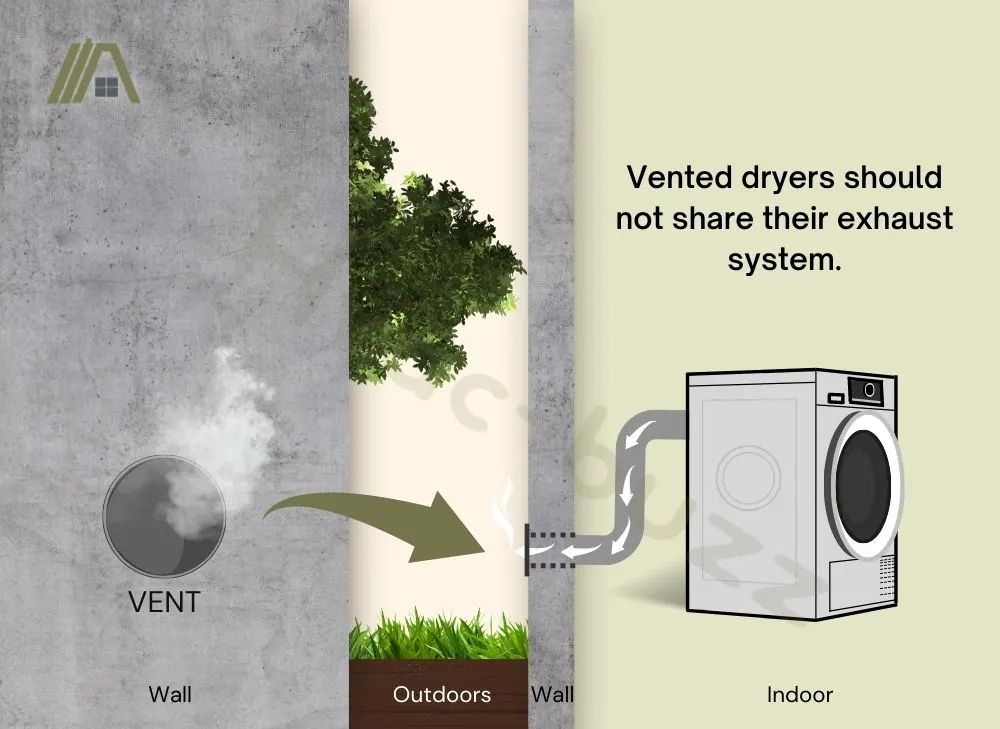

The code is very specific about the fact that vented dryers should not share their exhaust system. Section M1502.2 explicitly states that:

“Dryer exhaust systems shall be independent of all other systems and shall convey the moisture to the outdoors.

Exception: this section shall not apply to listed and labeled condensing (ductless) dryers.”

Therefore, no bathroom fans, extractor hoods, or any other systems and appliances, not even other dryers, should share their exhaust system with a dryer. This is partially due to the different safety requirements for different exhaust systems.

For example, dryer ventilation ducts and bathroom fan ducts have completely different requirements material-wise as they deal with different temperatures.

Combining dryer and exhaust fan ventilation would decrease both systems’ efficiency. It would also complicate the maintenance and increase the creation of duct clogs as well as the risk of various dangers, such as lint-related fire.

It is safe to say that similar differences apply to other exhaust systems as well.

As for two dryers not sharing ventilation, this is mainly because the ducting size requirements are designed to provide efficient airflow for one dryer only. The same size duct wouldn’t be able to keep up with the airflow that comes from ventilating two or more dryers.

There are better ways to vent multiple dryers.

Dryer Duct Materials

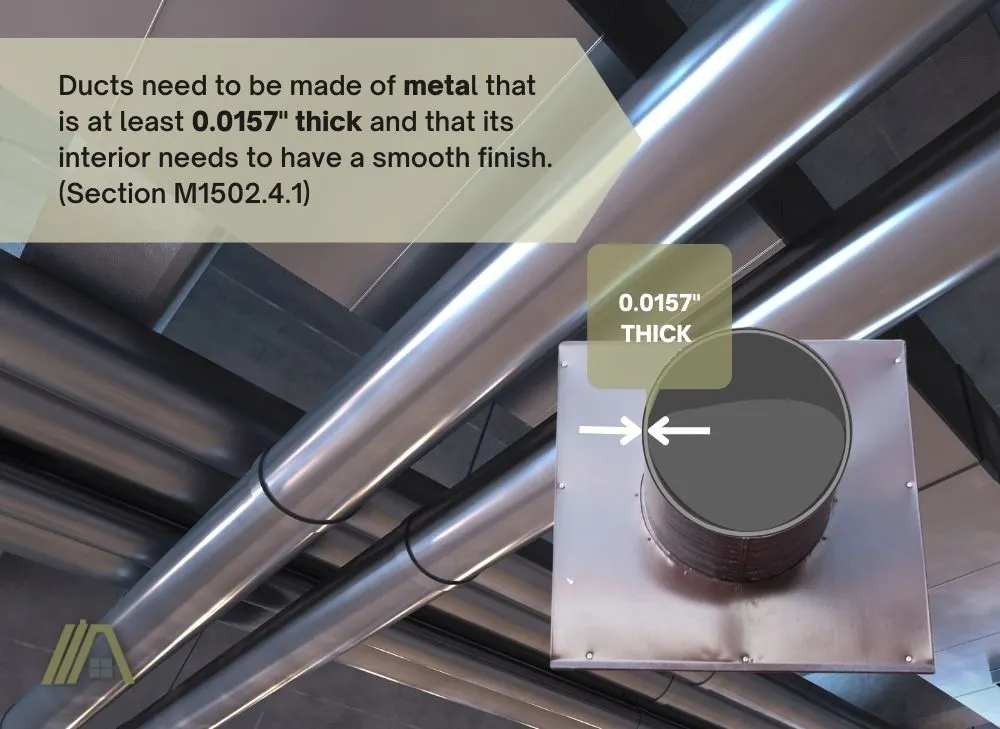

Some duct materials are simply better able to withstand the excessive heat and humidity exhausted by the dryer. The same applies to certain finishes and types of ducting.

Rigid metal ducting with a smooth finish is perfect because it can handle high temperatures and its smoothness makes it difficult for lint particles to build up inside of it.

This, on the other hand, cannot be said about flexible or ribbed ducting. Its kinks or ribs would essentially become a lint trap, which could cause blockages and lead to increased condensation, water leaks, and improper ventilation.

Not to mention the fire hazard that always comes with clogged dryer exhaust ducts. Speaking of the fire hazard, it is the very reason why you should not even consider using plastic ducts, as they are flammable.

Although the code does not explicitly say you cannot use a specific material, it does state that the ducts need to be made of metal that is at least 0.0157″ thick and that its interior needs to have a smooth finish (Section M1502.4.1).

These requirements essentially eliminate any PVC, ABS, or ribbed and foil ducts.

PVC Cannot Be Used for Dryer Ducts

PVC can be used for other home projects, like venting bathroom fans, but it cannot be used for dryer ducts.

The dryer duct environment makes using these plastic pipes dangerous and ineffective, which we will discuss shortly in detail. First, you should know that the danger is such that avoiding PVC in dryer ducts is not just a recommendation; it is an official regulation.

PVC Dryer Ducts Contravene Building Codes

According to Section M1502.4.1 of the International Residential Code (IRC), dryer exhaust ducts must be made of metal (at least 0.0157” thick). Thus, using plastics like PVC and ABS violates the building codes.

Reasons for the Prohibition

As mentioned, not allowing PVC dryer ducts is not a purposeless regulation to make your life as a homeowner more difficult and expensive. There are very real safety-and function-related reasons for this prohibition.

Heat Intolerance Threshold

Dryers are heat-generating appliances. The average drying temperature of dryers is 125 °F to 135 °F (51.6 °C to 57.2 °C). These are not mickey mouse temperatures.

PVC has a recommended operating temperature of up to 140 °F (60 °C). This is very close to the average dryer temperature. Too close to be safe.

But what happens at and over PVC’s maximum operating temperature? The pipes won’t suddenly burst into flames—that happens at temperatures above 734 °F (390 °C). However, the PVC pipes will begin to warp and may even smoke.

Exhaust Duct Power Ventilators

If you are searching for any guidance on what kind of power ventilator you need for your brand new dryer, you will come across it in Section M1502.4.4.

There you will learn that the power ventilator should be installed according to the manufacturer’s instructions, and it needs to:

“…conform to UL 705 for use in dryer exhaust duct systems. …”

But what is UL 705?

It is a certification that the motor of the ventilator is powerful and resilient enough to withstand various abnormal circumstances. In the case of dryers, these circumstances include high temperatures but also any potential voltage fluctuations.

It is basically a confirmation that the motor is safe to be used with a dryer duct power ventilator.

No Booster Fans

Another reason why it is important to have a powerful enough exhaust duct power ventilator is that it eliminates any need for a booster fan. Booster fans are considered to be a safety risk and, therefore, they are not permitted by code:

“Domestic booster fans shall not be installed in dryer exhaust systems.”

Section M1502.4.5

But what makes booster fans too dangerous for dryer exhaust duct?

They are designed to provide an extra kick to the exhaust system and increase air suction and airflow. This may sound like a great idea, especially if your dryer exhaust duct is long. However, booster fans become a hazard when there is a fire.

If you were using booster fans and your dryer started a fire, the fans would enable the fire to spread throughout the house more quickly. Since dryers are a common cause of house fires (National Fire Protection Association), it is important to take precautions.

Size of the Duct

Transition Duct

Unlike the rest of the dryer ventilation ducts, the transition ducts are generally flexible ducts that can be made from various materials such as foil or different types of aluminum.

That said, there are four important requirements they need to meet in order to abide by the IRC Subsection M1502.4.3:

- The transition ducts used to connect the dryer to the exhaust duct system need to be a single length, meaning they cannot have any connecting sections.

- Only transition ducts that meet the UL 2158A standard and are, thus, listed and labeled in accordance with this standard can be used.

- Their length cannot be more than 8 ft (2438 mm).

- The ducts are not to be concealed within construction; in other words, they shall not pass through walls, floors, and so on.

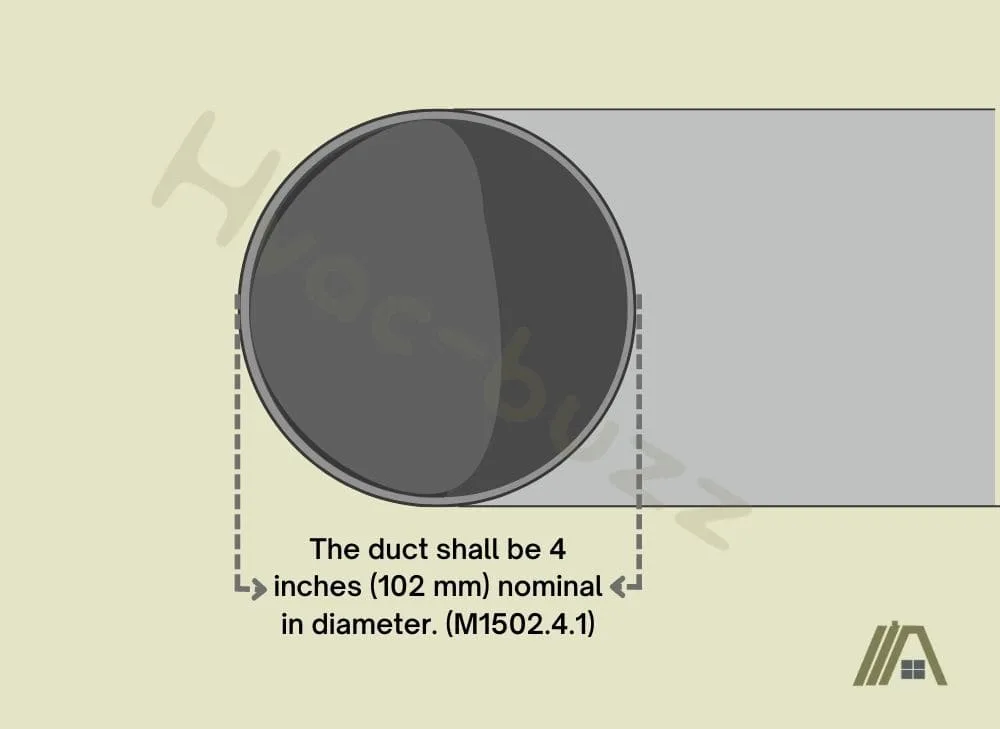

Diameter

The IRC is pretty clear about the requirements with regards to the dryer duct diameter:

“… The duct shall be 4 inches (102 mm) nominal in diameter.”

M1502.4.1

Ducts that are 4″ in diameter are shown to provide efficient enough airflow to ventilate one dryer.

Any ducts smaller than that are considered a hazard. They could cause stress on the dryer and shorten its lifespan. They also rapidly increase the risk of duct blockages and, therefore, could cause leaks or fire.

Length of the Duct

The IRC clarifies that the dryer exhaust duct shall not exceed the length of 35 ft (10 668 mm). This doesn’t include the length of the transition duct, only the duct running from the connection between the transition and exhaust ducts to the outlet terminal (outside vent).

However, this 35 ft limit only applies to ducts that don’t have any turns. If the duct has added fittings, the maximum length needs to be adjusted. Section M1502.4.6.1 provides a table according to which you can calculate what length various fittings count for.

For example, a smooth 45-degree elbow with a 6″ radius is the equivalent length of 1 ft of ducting, while a smooth 90-degree elbow with a 6″ radius counts for 1’9″ inches of ducting.

As with other dryer ventilation requirements, the manufacturers have the final word when it comes to the length of the duct. They shall specify it in the installation instructions, and if they don’t specify the equivalent length of fittings, then the owner shall abide by the code.

However, a power ventilator is perhaps the most important factor in determining how long the ducting can be. This ventilator is responsible for maintaining sufficient airflow inside the ducts to ensure all the air from the dryer is exhausted outside. Some models can create more airflow than others.

Therefore, it is important to consider how powerful the ventilator is and adjust the length of the ducting according to it. For this reason, Subsection M1502.4.6.3 specifies that:

“The maximum length of the exhaust duct shall be determined in accordance with the manufacturer’s instructions for the dryer exhaust duct power ventilator.”

Putting the Ducts Together

Never Deform the Duct

One of the most important rules when installing ducts is to make sure they are not deformed (Section M1502.4.2) or damaged in any way, as such ducts could cause blockages or air leaks. Either of these options presents a safety hazard for various reasons.

As mentioned before, blocked ducts can start a fire or cause water leaks that escalate to mold issues. Leaky dryer exhaust ducts could also cause humidity problems, worsen air quality, or eventually even lead to structural damage.

Support Intervals

The code calls for the ducts to be supported at least every 12 ft (Section M1502.4.2). These supports need to keep the duct properly secured but should only be looped around the duct and not screwed directly to it.

For this reason, dryer ducts are generally secured with pipe straps made from a material that can handle high temperatures well. These Stainless Steel 4 Inches Diameter Tube Straps (amazon link) are a good example.

Connecting Sections of Duct

Each duct typically has an insert end which is the end that is crimped. If your duct doesn’t have the insert end, you need to crimp one yourself. To do so, you will need a crimp tool.

The code requires you to connect the ducts in the direction of airflow (Section M1502.4.2), which can be done by inserting the insert end of the duct into the regular end of the next duct.

Any duct joints should be mechanically fastened and sealed in accordance with Section M1601.4.1. This states which of UL 181 standards different types of sealants have to be compliant with.

In the case of dryer exhaust ducts, it is important that the sealant can handle and is listed for high temperatures.

When fastening the ducts, it is prohibited to use screws or other fasteners that would protrude more than 1/8” into the inside of the duct as such fasteners would catch lint and potentially start causing blockages.

Termination of Dryer Exhaust Ducts

Must Vent Outdoors

The code requires all the dryer ducts to be vented directly outside (Section M1502.3). This is because the air they exhaust is hot, contains lint, and is full of moisture.

If this air was not exhausted directly outside, but let’s say into a room in your house, attic, or your crawlspace, it could cause many serious issues over time.

Furthermore, it would put you and the people around you in danger. The same is true for dryers utilizing condenser boxes or indoor dryer vent kits.

Some of the issues include mold growth, greater load on the HVAC system, or bad air quality inside your house.

In worst cases, this could even cause a fire. Not to mention that if you are venting a gas dryer inside, there is the potential danger of carbon monoxide poisoning.

Install Backdraft Damper

Section M1502.3 also specifies that the exhaust duct terminations need to have a backdraft damper installed. But why is that?

The primary purpose of a backdraft damper is to stop the colder outdoor air from getting inside your warm house, saving you some money on the heating.

Another important role it plays in dryer ventilation is that it helps to keep the exhaust duct clean by preventing any dirt, debris, rain, snow, or animals from getting into the ducting and causing blockages.

Clogged ducts can lead to fires or structural damage and health issues related to water leaks and excessive humidity.

Keeping the dryer exhaust ducting clean is a crucial step in preventing all of these, and the truth is that you simply won’t be able to keep the ducts as clean as you need them if you don’t have a backdraft damper installed in place.

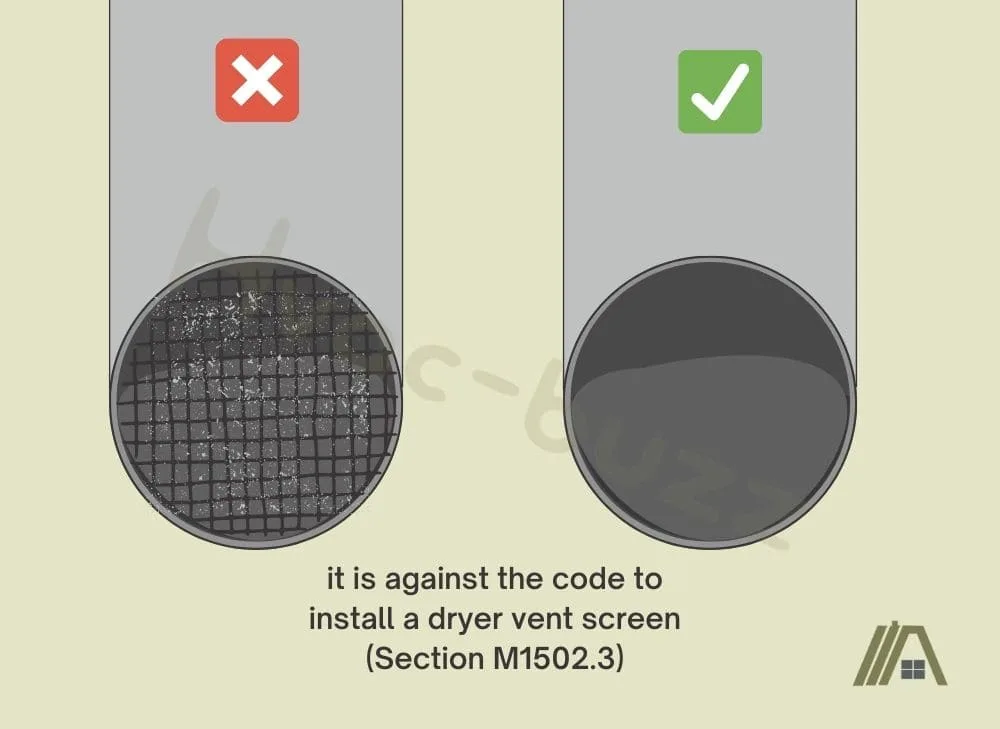

No Screens

Although vent screens are helpful in stopping rodents and vermin from getting into the ducts and through them into the house, it is strongly advised to forgo this line of protection for dryers. In fact, it is against the code to install a dryer vent screen (Section M1502.3).

In a way, the lack of vent screen is one more reason why it is so important to install and properly maintain a good backdraft damper. But what is the big difference between the two? Why is one mandatory and the other prohibited?

While the backdraft damper allows the moister and lint-filled air to escape the ducts freely, the screen tends to prevent the lint from escaping.

The lint, therefore, collects in the screen, which eventually makes it impossible for the air to escape the ducts. This could again easily lead to fire as lint is highly flammable, and accumulations of lint in dryer ducting or inside the dryer itself are considered a fire hazard.

Located so Air Cannot Re-Enter Home

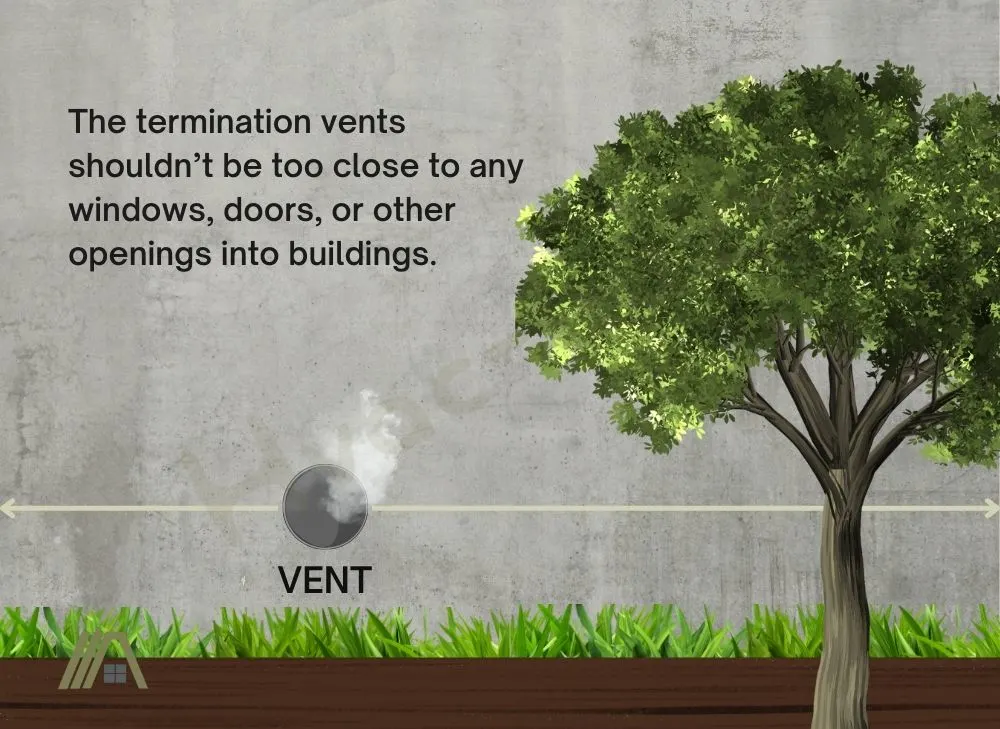

For the same reason we don’t want the dryer to vent the air inside, we also need to stop the already vented air from re-entering our home. If it did, it would still have a chance to cause the same damage as venting into the house would.

In order to prevent the moist air from getting back inside, the termination vents shouldn’t be too close to any windows, doors, or other openings into buildings.

Again, it is left up to manufacturers to come up with and provide you with the dryer duct termination location instructions best suited to the exact dryer you have.

Thus, different models can have slightly different termination instructions, such as one is allowed to vent through a soffit and the other is not or one may vent through the floor but another may not.

However, if the manufacturer does not specify what should be the duct termination location, then it is necessary to look into the IRC Section M1502.3 where it is clearly stated that:

“… the exhaust duct shall terminate not less than 3 feet (914 mm) in any direction from openings into buildings, including openings in ventilated soffits.”

Furthermore, it is also strictly prohibited to terminate exhausts less than 10 ft from mechanical air intake openings, such as fresh air inlets.

Exhaust Must Not Interfere With Neighbors

The rule that dryer exhaust shall not terminate closer to a building opening than 3 ft doesn’t only apply to your own house but also to your neighbor’s.

In order to prevent any neighbor conflict and protect people’s health, it is forbidden by code (Section M1504.3) for the exhaust to terminate less than 3 ft from property lines altogether.

For more information about dryer vent clearance requirements, check out this article.

Same Size as Duct

Using a vent cap smaller than the duct could disrupt the airflow and create blockages, which would, in turn, cause many serious issues that I have touched on in previous sections.

For this reason, the vent cap should be the same size as the duct (Section M1502.3.1), i.e., it should not be any smaller than 4″ in diameter.

Minimum Open Area

Since the whole purpose of the dryer exhaust system is to provide an unobstructed way for the air to get outside, it makes sense that the passageway of the duct terminals cannot be diminished in size.

To further ensure efficient dryer ventilation, the code dictates that the minimum open area provided by the exhaust terminals cannot be less than 12.5 square inches or 8065 mm2 (Section M1502.3.1).

Whenever you have a system that actively removes air from the house, like a dryer, then you need to consider if makeup air is required for that appliance or in that room: Laundry Room Makeup Air Requirements.

Never Run a Vented Dryer Without the Dryer Vent

At first, the vent’s function of removing a little moisture and dust may not sound particularly important. However, failing to vent your dryer outside can pose multiple safety risks for your home and your body.

It may not seem like this is the case at first, but much of the damage caused by not venting your dryer is likely to occur gradually. You won’t become aware of it until it is too late to prevent the major issues that it will inevitably cause.

On top of these issues, which I will take you through in the next section, venting a dryer inside is against the International Residential Code (IRC M1502.2). So, it is safe to assume that not connecting the dryer to a vent, which essentially means that all the used air ends up being vented inside, is also against the code.

Not to mention the manufacturers specifically state that vented dryers need to be connected to a dryer vent. They provide precise instructions on how to do that in their manuals, some even stating that:

“Failure to follow these instructions can result in death or fire.”

But if all this is not enough for you, let’s look at the potential safety risks you would be facing if you didn’t connect your dryer to a vent.

Safety Risks of Running Vented Dryer With No Vent

The Quality of the Air Will Rapidly Decrease

Most of the lint created by a dryer is collected by its lint screen. However, lint particles on their own are very small, and some will always find their way into places they shouldn’t be in.

This means that by not routing your dryer’s vent outdoors, you can drastically increase the amount of dust and lint in your home.

This can cause sneezing or other breathing-related irritation. Not to mention, you’ll have to clean more frequently to try and keep all that lint at bay.

Not Venting Dryer Can Cause Mold and Mildew

One of a dryer vent’s primary purposes is to remove moisture, but without a route to the outdoors, this moist air will linger in your home.

Moist, humid air is never a great thing indoors, as it creates an ideal environment for mold and mildew to grow. Over time, this can even cause structural damage.

These are not just costly problems to fix, but breathing in moldy air isn’t good for your health either. It’s always important to prevent its growth, whether in the bathroom, the laundry room, or anywhere else in the home.

The Dryer Can Become a Fire Hazard

Not only can the buildup of lint worsen the air quality, but it provides another type of hazard—it increases the risk of a fire.

The lint that makes it through a filter and out the vent will instead be free to float in your home. Since dryers operate by sucking in air to heat up, it’s possible for this lint to be sucked back into your dryer and settle in dangerous locations.

For example, if enough lint builds up inside your dryer by the heating element, it could start a fire.

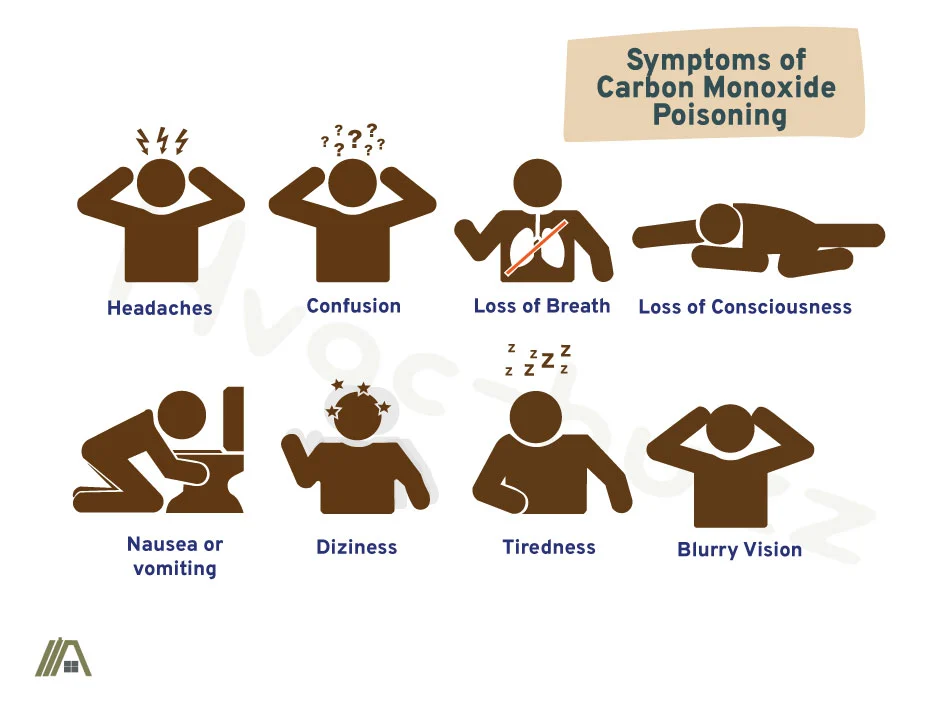

Risk of Carbon Monoxide Poisoning From Gas Dryers

On top of all the other concerns regarding failure to ventilate a dryer, a gas dryer without proper ventilation becomes a severe health hazard.

When gas burns, it releases carbon monoxide. If you breathe in too much of it, you may experience symptoms of carbon monoxide poisoning, including dizziness, confusion, chest pain, and weakness.

In a high enough dose, carbon monoxide can be deadly.

Suffice it to say that you absolutely want to vent your dryer to the outside, especially if you own a gas dryer.

Sources

https://cwservicesinc.com/dryer-ducts-are-yours-up-to-code/

https://www.aerovent.com/fan-testing-services/ul-705-safety-testing/

https://www.hunker.com/13415620/how-to-connect-duct-work

https://www.youtube.com/watch?v=fR5rLgEsitM

https://www.familyhandyman.com/project/how-to-install-a-dryer-vent/